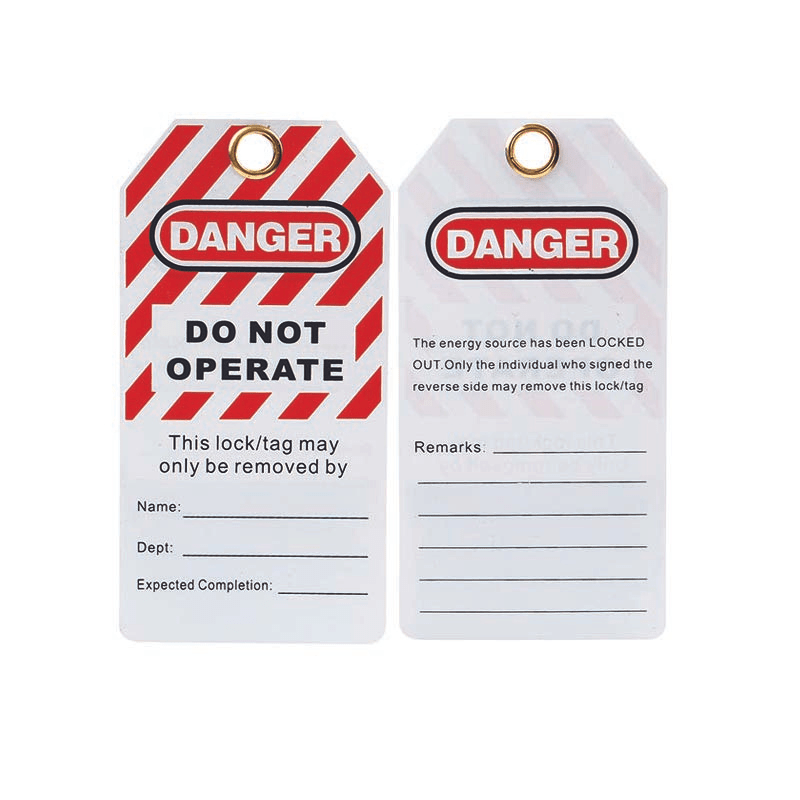

For decades, the familiar sight of a paper tag and a physical padlock has been the gold standard for workplace safety during machine maintenance. But in 2025, that standard is no longer enough. As industrial environments become more complex and regulatory oversight intensifies, traditional, paper-based Lockout Tagout (LOTO) processes are revealing critical weaknesses. They are slow, prone to error, and create a compliance nightmare. In this new era of digital transformation, relying on manual LOTO isn't just inefficient—it's a direct risk to your operations, your finances, and most importantly, your people. The stakes have never been higher, with regulatory fines, crippling downtime, and preventable accidents hanging in the balance.

The Rising Compliance Pressure

Regulators are losing patience with outdated safety protocols. In 2025, agencies like OSHA in the United States and EU-OSHA in Europe are not just checking if a LOTO program exists; they are dissecting its execution, documentation, and consistency. Enforcement trends show a clear shift towards increased scrutiny of procedural accuracy and record-keeping. Fines for violations are becoming more severe, with inspectors specifically targeting gaps that digital systems effortlessly solve.

Consider a recent (and very real) scenario: a large manufacturing plant was fined over $150,000 for LOTO violations. The investigation revealed that while procedures existed on paper, they were not consistently applied across shifts. Auditors found incomplete paper logs, illegible signatures, and instances where workers followed outdated procedures stored in dusty binders. This is no longer an outlier; it is the new reality for companies failing to modernize their safety systems.

What “Digital Lockout Tagout” Actually Means

Moving to digital LOTO is about more than just replacing a paper form with a PDF on a tablet. It's about transforming the entire process into a streamlined, accountable, and data-driven workflow. A true digital LOTO system provides:

- Centralized, Digital Procedure Management: All LOTO procedures are stored in a single, cloud-based platform. When a machine is updated, the procedure is updated once, and everyone instantly has access to the latest version on their mobile device or workstation.

- Real-time Approvals and Electronic Signatures: Supervisors can review and approve lockout requests from anywhere, instantly. Technicians use their mobile devices to electronically sign off on each step, creating a time-stamped, unforgeable record of every action taken.

- Audit Trails, Notifications, and Accountability: The system automatically generates a complete, searchable audit trail for every LOTO event. It logs who did what, where, and when. Automated notifications can alert managers to delays, non-compliance, or the completion of a task, ensuring everyone is in the loop.

Key Benefits of Going Digital in 2025

The shift to a digital platform delivers immediate and measurable benefits across safety, efficiency, and compliance.

- Improved Compliance and Reduced Risk: With perfect, easily accessible records, audits become simple. The risk of human error is drastically reduced because procedures are presented step-by-step, ensuring nothing is missed.

- Faster Execution and Reduced Downtime: By eliminating the administrative runaround, digital LOTO significantly shortens the time it takes to safely isolate and re-energize equipment. This translates directly to reduced Mean Time to Repair (MTTR) and increased production uptime.

- Integration with Broader Safety Systems: Digital LOTO doesn't live on an island. It can integrate with other critical EHS platforms like Permit to Work (PTW), training record databases, and asset management systems. This creates a holistic safety ecosystem where, for example, the system can automatically verify a worker’s training certification before allowing them to perform a lockout.

- Data Insights for Continuous Improvement: Every digital LOTO event generates valuable data. You can analyze this data to identify which machines require the most frequent LOTO, where bottlenecks are occurring in the process, and other key trends to drive continuous safety improvements.

Industry Adoption: Who’s Making the Switch?

The transition to digital LOTO is happening across all major industrial sectors, where safety and efficiency are paramount.

- Pharmaceuticals & Life Sciences: In an industry governed by cGMP (current Good Manufacturing Practices), the bulletproof audit trails and version control of digital LOTO are essential for maintaining compliance and ensuring product safety.

- Manufacturing: For complex assembly lines, reducing downtime is critical. Digital LOTO helps automotive and consumer goods manufacturers get equipment back online faster while managing hundreds of energy isolation points with precision.

- Food & Beverage: Efficiency during sanitation and changeovers is key. Digital LOTO streamlines the process, ensuring safety without slowing down production schedules in this fast-paced environment.

Why Waiting Is No Longer an Option

In 2025, digital transformation is not a buzzword; it's the operational standard for Environment, Health, and Safety (EHS). Continuing to rely on a manual LOTO process is now a significant competitive disadvantage. It introduces unnecessary risk, slows down your operations, and leaves you vulnerable to ever-stricter regulatory enforcement. The trend is clear: regulators increasingly expect the level of accuracy and accessibility that only digital record-keeping can provide. Sticking with paper is a bet against the future.

How to Get Started with Digital Lockout Tagout

Making the switch is more straightforward than you might think. A phased approach ensures a smooth transition and builds buy-in from your team.

- Assess Current Processes and Gaps: Map out your existing LOTO workflow. Identify the pain points, administrative bottlenecks, and compliance risks.

- Pilot a Digital Solution: You don't have to go all-in at once. Start with a single production line, a specific department, or a set of critical equipment to pilot a digital LOTO solution.

- Involve Operators, Safety Managers, and Auditors: Your frontline workers are your most important stakeholders. Involve them in the selection and rollout process to ensure the system is user-friendly and meets their real-world needs. Their feedback is invaluable for successful adoption.

Conclusion

The question is no longer if you should digitize your Lockout Tagout program, but how quickly you can do it. The forces of regulatory pressure, operational efficiency, and workplace safety are all pointing in the same direction. Manual LOTO is an analog solution in a digital world—and it's a liability your organization can no longer afford. The time to act is now.