Lockout/Tagout (LOTO) procedures are a critical component of workplace safety, yet they remain one of the most frequently cited violations by the Occupational Safety and Health Administration (OSHA). Failure to properly implement LOTO can lead to severe injuries and fatalities, as well as significant financial penalties for businesses. This post will detail the most common LOTO violations and provide clear, actionable steps to ensure your business remains compliant and your employees stay safe.

Table of Contents

What is LOTO?

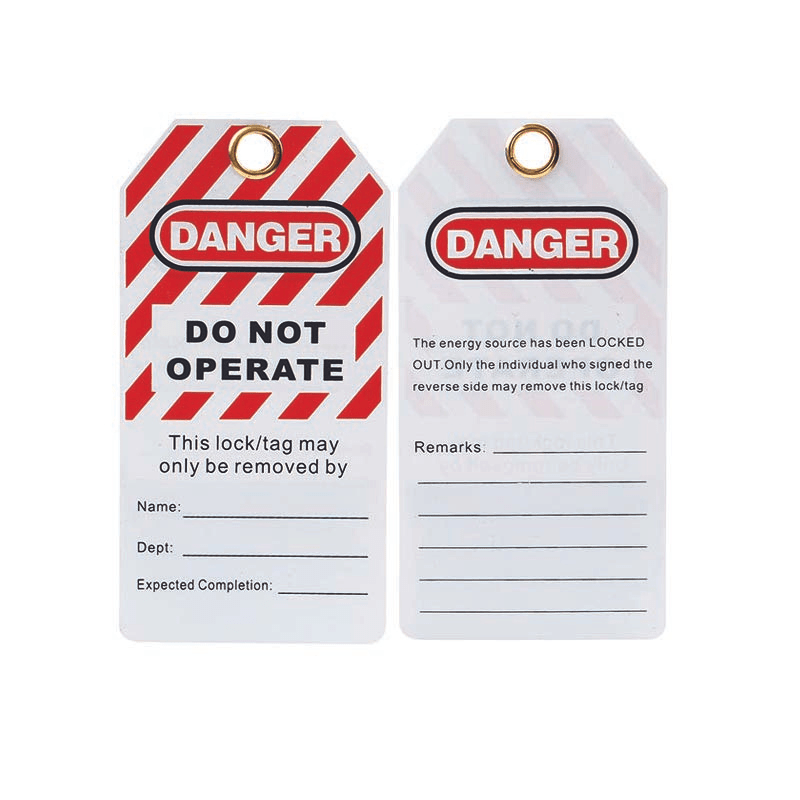

Lockout/Tagout is a safety procedure used in industry and research settings to ensure that dangerous machines are properly shut off and not able to be started up again prior to the completion of maintenance or servicing work. It requires that hazardous energy sources be "isolated and rendered inoperative" before work is started on the equipment in question. The isolated power sources are then locked and a tag is placed on the lock identifying the worker who has placed it. The worker then holds the key for the lock, ensuring that only he or she can start the machine. This prevents accidental startup of a machine while it is in a hazardous state or while a worker is in direct contact with it.

Top 5 OSHA LOTO Violations

Based on OSHA's citation data, a few key areas consistently emerge as major stumbling blocks for employers. Here are the top five LOTO violations and how you can avoid them.

1. Lack of a Written Energy Control Program

The Violation (29 CFR 1910.147(c)(4)): The most fundamental LOTO violation is the failure to develop, document, and utilize a formal energy control program. This includes creating specific procedures for each piece of equipment that could release hazardous energy. A generic, one-size-fits-all approach is not compliant.

Common Pitfalls:

- Having no written LOTO procedures at all.

- Procedures that are not machine-specific.

- Failing to detail the exact steps for shutting down, isolating, blocking, and securing equipment.

- Not specifying the steps for placing, removing, and transferring LOTO devices.

How to Stay Compliant:

- Develop a comprehensive, written energy control program that outlines the entirety of your LOTO policy.

- Create and document machine-specific LOTO procedures for every piece of equipment that requires it.

- Each procedure should clearly identify the type and magnitude of the hazardous energy, and the specific means to control it.

- Make these procedures readily accessible to all employees who perform service or maintenance. A great way to do this is with Lockout Stations and Shadowboards, which keep procedures and devices organized and visible.

2. Inadequate Employee Training

The Violation (29 CFR 1910.147(c)(7)): OSHA requires employers to provide training to ensure that employees understand the purpose and function of the energy control program. There's a critical distinction between "authorized" and "affected" employees.

Common Pitfalls:

- Failing to train "authorized employees" (those who perform the LOTO) on how to recognize hazardous energy sources, the type and magnitude of the energy, and the methods for energy isolation.

- Not training "affected employees" (those who operate the machinery or work in the area) on the purpose and use of the LOTO procedure.

- Lack of retraining when job duties change, new equipment is introduced, or procedures are updated.

- Failure to document training sessions.

How to Stay Compliant:

- Develop a training program that is tailored to the specific needs of authorized, affected, and "other" employees.

- Training must be conducted by a qualified person and should include both classroom and hands-on components.

- Keep detailed records of all training, including the employee's name, date of training, and the topics covered.

- Provide refresher training at least annually and whenever there are changes in the workplace that could affect the LOTO program.

3. Failure to Conduct Periodic Inspections

The Violation (29 CFR 1910.147(c)(6)): An energy control program is not a "set it and forget it" document. OSHA mandates that employers conduct periodic inspections of their LOTO procedures at least annually to ensure they are being followed and remain effective.

Common Pitfalls:

- Not performing inspections at all.

- Having the inspection performed by the same employee who uses the procedure, rather than an authorized employee who does not.

- Not correcting deficiencies identified during the inspection. Failing to certify that the periodic inspections have been performed.

How to Stay Compliant:

- Designate a qualified, authorized employee to conduct the annual inspection for each LOTO procedure. The inspection should include a review of the procedure with the employees who use it, to ensure they understand their responsibilities. Document each inspection with a certification that identifies the machine or equipment, the date of the inspection, the employees included, and the inspector's name. Use these inspections as an opportunity to identify and correct any weaknesses in your LOTO program.

4. Improper Application of LOTO Devices

The Violation (29 CFR 1910.147(d)): Having a great procedure is meaningless if it isn't followed correctly. This violation pertains to the failure to properly apply LOTO devices in the correct sequence.

Common Pitfalls:

- Not de-energizing or shutting down equipment before applying locks and tags. Failing to disconnect the equipment from its energy sources. Not verifying that the isolation of the equipment is effective. This is a critical step that is often missed.

How to Stay Compliant:

- Ensure your machine-specific procedures detail the exact sequence of actions: prepare for shutdown, shut down the machine, isolate energy sources, apply LOTO devices, release stored energy, and verify isolation. Equip your employees with the correct LOTO devices for the job.

- The Lock Box offers a comprehensive range of products, including: Safety Padlocks, Hasps for multiple-worker lockout, Cable Lockout for unique energy isolating devices A full range of Electrical and Valve Lockout devices.

5. Failure to Identify and Isolate All Energy Sources

The Violation: A frequent and dangerous oversight is failing to account for all forms of hazardous energy. This goes beyond just electrical power.

Common Pitfalls:

- Only locking out the main electrical disconnect while ignoring other energy sources like pneumatic lines, hydraulic systems, or thermal energy. Forgetting about stored energy, such as compressed air in a pneumatic line, pressure in a hydraulic accumulator, or a heavy part that could fall due to gravity.

How to Stay Compliant:

- During the development of your machine-specific procedures, conduct a thorough hazard assessment to identify every potential energy source. This includes electrical, mechanical, hydraulic, pneumatic, chemical, and thermal energy. Your procedures must include steps for dissipating or restraining any stored or residual energy. Use specific lockout devices for different energy sources, such as Pneumatic Lockout for air lines and various Valve Lockouts for controlling the flow of liquids and gases.

A Proactive Approach to LOTO Compliance

Avoiding OSHA citations is not just about ticking boxes; it's about creating a culture of safety. A successful LOTO program is built on three pillars:

- A Thorough, Written Program: Your energy control program is the foundation of your LOTO procedures. It must be comprehensive, machine-specific, and regularly updated.

- Comprehensive Training: Your employees are your first line of defense against accidents. Ensure they have the knowledge and skills to perform LOTO safely and effectively.

- The Right Equipment: Providing high-quality, durable, and appropriate LOTO devices is essential. Equipping your team with complete Lockout Kits ensures they have everything they need to perform their jobs safely.

Conclusion

Lockout/Tagout compliance is a non-negotiable aspect of workplace safety. By understanding the common pitfalls and taking a proactive approach to developing, implementing, and maintaining your energy control program, you can protect your employees from harm and your business from costly citations. The Lock Box is your partner in safety, offering the high-quality products and expertise you need to build a world-class LOTO program. Visit www.thelockbox.ch to explore our full range of safety solutions.