Table of Contents

Why Pneumatic LOTO is Often Overlooked (and Why It Shouldn't Be)

Pneumatic systems are ubiquitous. They power everything from small hand tools in workshops to massive industrial machinery. Because compressed air is often perceived as "safer" than electricity or hydraulics, the risks associated with pneumatic energy can be underestimated. This is a dangerous misconception.

Here's why pneumatic LOTO is critical:

- Stored Energy: Even after the air compressor is shut off, significant energy can remain stored in receivers, accumulators, and pipelines. This stored energy can be released unexpectedly, causing rapid and forceful movement of machinery components.

- Invisible Hazard: Unlike electricity, where a visible spark or arc might indicate danger, compressed air is invisible. A sudden release might not be apparent until it's too late.

- Rapid Actuation: Pneumatic actuators (cylinders, motors) can move with incredible speed and force, posing crushing, pinching, and impact hazards.

- Noise: The sudden release of compressed air can create a loud, startling noise, potentially causing hearing damage or leading to secondary accidents due to distraction.

- Flying Debris: A ruptured hose or fitting can send projectiles flying at high speeds.

- Suffocation/Asphyxiation: Some pneumatic systems use inert gases (e.g., nitrogen). A leak in a confined space could displace oxygen, creating an asphyxiation hazard.

Unique Challenges of Pneumatic LOTO

Compared to electrical LOTO, pneumatic systems present some distinct challenges:

Residual Pressure: The primary challenge is dealing with residual pressure. Simply turning off the compressor is not enough. The system must be completely depressurized before it's safe to work on.

Multiple Isolation Points: Pneumatic systems often have complex networks of valves, regulators, and manifolds. Identifying and isolating all relevant energy sources can be more complicated than a single electrical disconnect.

Variety of Fittings and Connections: Pneumatic systems use a wide range of fittings, connectors, and hoses. Selecting the correct LOTO devices to fit these various components can be challenging.

Lockout Device Compatibility: Standard electrical lockout devices (e.g., circuit breaker lockouts) are often not suitable for pneumatic systems. Specialized devices are required.

Training Gaps: Workers may be less familiar with the specific hazards and procedures for pneumatic LOTO compared to electrical LOTO.

Best Practices for Pneumatic LOTO

1. Thorough Hazard Assessment and Procedure Development

Identify All Energy Sources: This includes not only the main air compressor but also any accumulators, receivers, or auxiliary air supplies.

Map the System: Create a detailed schematic or diagram of the pneumatic system, clearly identifying all valves, regulators, actuators, and potential isolation points.

Develop Equipment-Specific Procedures: General LOTO procedures are a starting point, but each piece of pneumatically powered equipment should have its own specific, written LOTO procedure. This procedure should detail:

-

- The specific energy sources to be isolated.

- The location of all isolation points.

- The steps for safely de-energizing the system (including bleeding off residual pressure).

- The types of LOTO devices required.

- Verification procedures to ensure zero energy state.

Regular Review and Updates: Procedures should be reviewed and updated regularly, especially after any modifications to the equipment or system.

2. Proper Isolation and De-energization

Shut Off the Air Supply: Turn off the main air compressor and any auxiliary air sources.

Isolate the System: Close all relevant valves to isolate the section of the system being worked on. This may involve multiple valves, including:

- Main Shut-Off Valves: Located at the air supply source.

- Branch Isolation Valves: Located on individual lines feeding specific equipment.

- Exhaust Valves: Designed to release trapped air pressure.

Bleed Off Residual Pressure: This is the critical step. Use designated bleed valves or other safe methods to completely depressurize the system. Never assume that closing a valve is enough.

- Slow, Controlled Release: Open bleed valves slowly and carefully to avoid a sudden, uncontrolled release of air.

- Monitor Pressure Gauges: Use pressure gauges to confirm that the system is completely depressurized. The gauge should read zero.

Lockout and Tagout: Once the system is depressurized, apply appropriate lockout devices and tags to all energy isolation points.

3. Selecting the Right LOTO Devices

- Ball Valve Lockouts: Used to secure ball valves in the closed position.

- Gate Valve Lockouts: Prevents operation of gate valves.

- Pneumatic Quick-Disconnect Lockouts: Designed to lock out quick-disconnect fittings.

- Universal Valve Lockouts: Works with different valve types.

- Lockout Hasps: Enables multiple workers to lock out a single energy source.

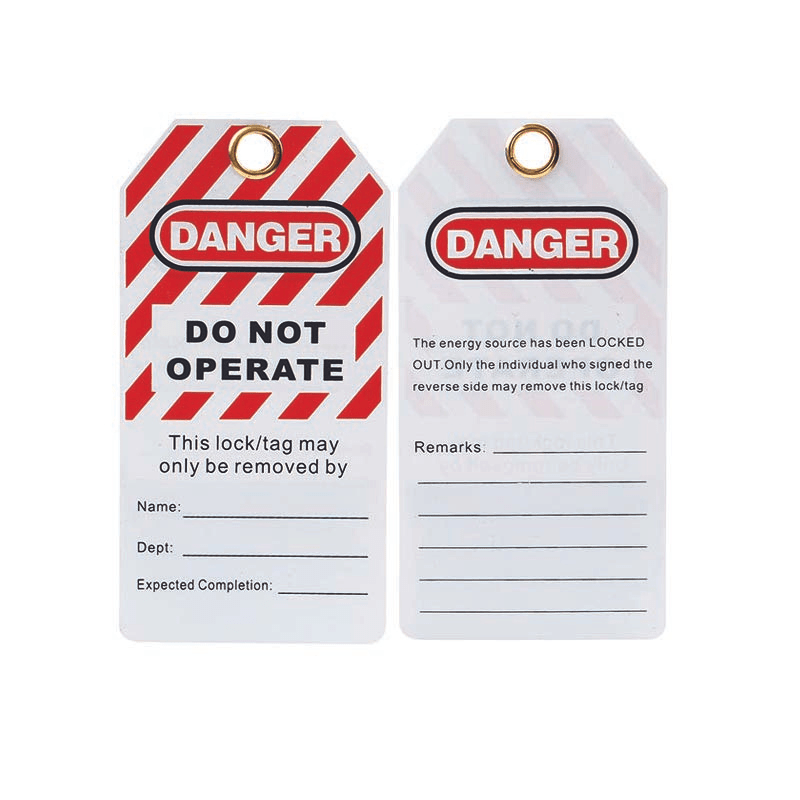

- Safety Tags: Labels indicating “DO NOT OPERATE.”

- Lock Boxes: Used when multiple energy sources need to be locked out.

4. Verification of Zero Energy State

Attempt to Operate: After applying LOTO devices, attempt to operate the equipment's normal start controls (e.g., buttons, levers). The equipment should not start or move.

Visual Inspection: Visually inspect the system to ensure that all actuators are in a safe position and that there are no signs of pressure.

Pressure Gauge Confirmation: Re-check pressure gauges to confirm they still read zero.

Secondary Verification Methods: Consider using additional verification methods, such as:

- Listening for Air Leaks: A hissing sound indicates residual pressure.

- Using a Pressure Indicator: Some specialized tools can detect even small amounts of residual pressure.

5. Comprehensive Training

Targeted Training: Provide specific training on pneumatic LOTO procedures to all employees who work on or around pneumatically powered equipment.

Hands-On Practice: Include hands-on practice with the actual LOTO devices and procedures.

Regular Refresher Training: Conduct regular refresher training to reinforce the importance of pneumatic LOTO and ensure that employees stay up-to-date on procedures.

Competency Assessment: Assess employee competency in performing pneumatic LOTO procedures.

6. Proper Removal of LOTO Devices

- Inspect the Work Area: Ensure that all tools and materials have been removed from the equipment.

- Verify Employee Safety: Confirm that all workers are clear of the equipment and in a safe location.

- Remove LOTO Devices: Each authorized employee should remove their own lock and tag.

- Restore Energy: Follow the equipment-specific procedure for restoring energy to the system, typically in the reverse order of the shutdown procedure.

- Test Operation: Carefully test the equipment's operation to ensure it is functioning correctly.

Real-World Example: LOTO on a Pneumatic Press

Let's consider a common scenario: performing maintenance on a pneumatic press.

- Preparation: Review the equipment-specific LOTO procedure, gather the necessary LOTO devices (ball valve lockout, quick-disconnect lockout, tags, hasp), and notify affected employees.

- Shutdown: Turn off the air compressor and close the main shut-off valve supplying air to the press.

- Isolation: Close any additional isolation valves on the press's air lines. Disconnect the main air hose from the press using a quick-disconnect fitting.

-

Lockout/Tagout:

- Apply a ball valve lockout to the main shut-off valve.

- Apply a pneumatic quick-disconnect lockout to the disconnected air hose fitting.

- Attach a safety tag to each lockout device. *If muliple employees are working on the press, use a hasp.

- De-energization: Open the bleed valve on the press (if equipped) to release any residual pressure. Monitor the pressure gauge to ensure it reads zero.

- Verification: Attempt to operate the press's controls. The press should not move. Visually inspect the cylinder and other moving parts to ensure they are in a safe position.

- Maintenance: Perform the required maintenance.

- Restoration: After completing the maintenance, follow the steps in reverse order to remove the LOTO devices and restore air pressure to the press. Test the press's operation.

The Importance of High-Quality LOTO Equipment

Using substandard or inappropriate LOTO devices can compromise safety. Invest in high-quality, durable, and clearly identifiable LOTO equipment from reputable suppliers. At The Lock Box we supply quality LOTO devices and ensure compliance and safety at competitive prices. Browse our high-quality LOTO products at The Lock Box.

Conclusion

Pneumatic LOTO is a critical safety practice that demands careful attention to detail. By understanding the unique hazards of compressed air systems, implementing robust procedures, using appropriate LOTO devices, and providing comprehensive training, you can significantly reduce the risk of accidents and create a safer workplace for everyone. Don't underestimate the power of stored energy – prioritize pneumatic LOTO and protect your workforce.