In the complex environment of industrial operations, Lockout/Tagout (LOTO) procedures are essential for workplace safety, beyond merely fulfilling regulatory requirements. These procedures, when properly implemented, can be the thin line between a routine day at work and an unforeseen disaster. Here at The Lock Box we understand the importance of LOTO in both routine maintenance and emergency shutdowns. Through our comprehensive range of lockout kits and stations, The Lock Box provides the essential tools needed to integrate LOTO procedures seamlessly into your maintenance routines.

The Essence of LOTO Procedures

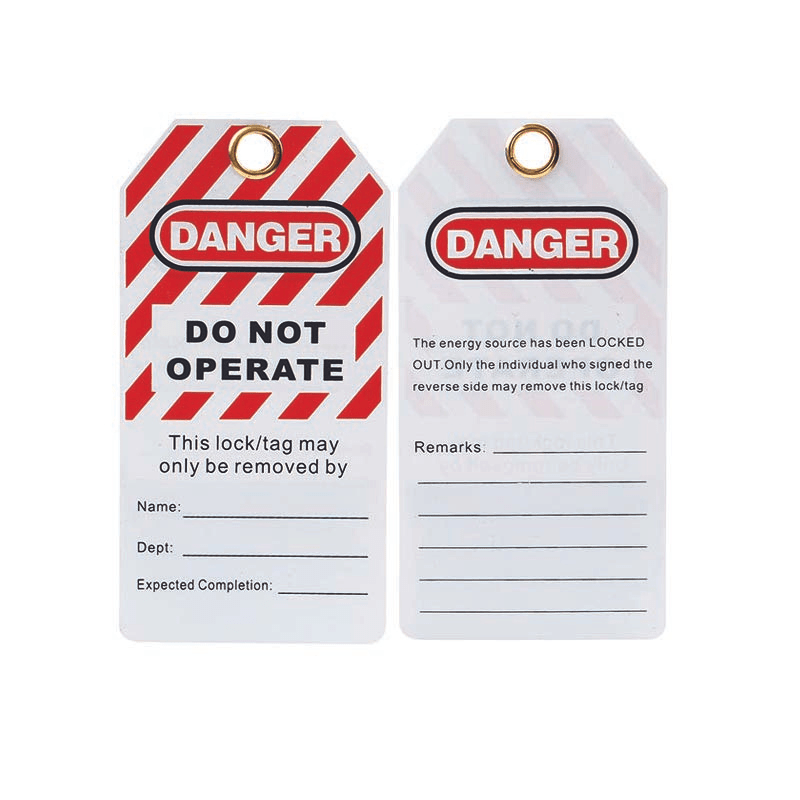

LOTO procedures serve a dual purpose – they protect the workers from the dangers of unexpected energization of machinery and ensure the machinery itself is safeguarded against inadvertent damage during maintenance. In essence, LOTO procedures involve isolating energy sources and locking and tagging them to prevent any accidental or unauthorized use. This is crucial during both routine maintenance, which is scheduled and planned, and emergency shutdowns, which are unplanned responses to imminent or actual hazardous events.

Routine Maintenance: A Planned Safety Approach

Routine maintenance stands as the backbone of industrial operations, ensuring the longevity and efficiency of machinery and equipment. This systematic process includes a variety of tasks such as regular inspections, cleaning, repairs, and the replacement of worn-out parts. The goal is twofold: to maintain optimal operational capacity and to uphold the highest safety standards.

Integrating Lockout/Tagout (LOTO) procedures into routine maintenance is not merely a best practice but a necessity. These procedures ensure that all energy sources are effectively isolated, making it impossible for machinery to be accidentally energized. The risks involved with maintenance tasks are manifold, ranging from electrical shocks to mechanical failures. Without proper LOTO protocols, these routine tasks could lead to severe injuries or even fatalities.

The Lock Box understands the critical nature of these procedures and has designed its lockout kits with the diverse demands of routine maintenance in mind. Each kit is a comprehensive solution, featuring an array of lockout devices, padlocks, and tags. This variety ensures that maintenance personnel are equipped with the necessary tools to securely isolate any machinery or equipment, tailored to the specific requirements of the task at hand. These kits are not just tools; they are a testament to The Lock Box's commitment to fostering safer work environments through meticulous planning and preparation.

Emergency Shutdowns: A Reactive Safety Measure

Emergency shutdowns are the fire drills of the industrial world — unforeseen, unplanned, but absolutely crucial. They are the immediate response to incidents that pose a significant risk to safety, health, or the environment. Whether it's a chemical spill, a gas leak, a fire breakout, or a critical system malfunction, the ability to quickly and effectively shut down operations can mean the difference between a controlled response and a full-blown disaster.

In such high-stakes scenarios, the speed and efficacy of LOTO procedures are paramount. The machinery and energy sources involved must be isolated swiftly to prevent exacerbation of the emergency. This rapid response is essential not only to safeguard personnel but also to minimize damage to the machinery and infrastructure.

Recognizing the urgent nature of these situations, The Lock Box offers lockout stations specifically designed for emergency use. These stations are strategically developed for accessibility and ease of use, ensuring that LOTO devices are readily available when seconds count. Positioned at central locations within the facility, these stations enable a quick deployment of LOTO procedures, effectively minimizing the time it takes to secure the area. This immediate accessibility is crucial in emergency situations, reducing the risk to personnel and ensuring that machinery remains isolated until it is safe to resume operations.

By providing these specialized lockout stations, The Lock Box empowers organizations to prepare for the worst-case scenarios. These stations are not just storage units for LOTO devices; they are a critical component of an emergency response strategy, designed to offer peace of mind and tangible safety solutions when they are needed most.

In both routine maintenance and emergency shutdowns, the integration of LOTO procedures is essential for maintaining a safe working environment. The Lock Box's comprehensive range of lockout kits and stations embodies this principle, offering practical, reliable solutions for a variety of industrial needs. Through careful planning, preparation, and the right tools, organizations can significantly reduce the risks associated with machinery and energy sources, safeguarding their most valuable assets: their people and their operations.

The Role of LOTO in Enhancing Safety

The integration of Lockout/Tagout (LOTO) procedures into both routine maintenance and emergency shutdowns is a critical factor in bolstering workplace safety. This comprehensive approach provides a systematic method for controlling hazardous energies, significantly mitigating risks associated with industrial operations. Here’s an expanded view on the pivotal roles LOTO plays in enhancing safety:

Prevention of Accidental Energization

At the heart of LOTO procedures lies the goal to prevent the unintended activation of machinery, a scenario that becomes particularly perilous during maintenance activities. Maintenance tasks often require workers to be in proximity to or directly interact with machinery, placing them at heightened risk if an accidental startup were to occur. Through the application of LOTO protocols, energy sources that could potentially activate the machinery are securely locked out. This decisive action eliminates the risk of accidental energization, thereby safeguarding workers from injuries that could result from unexpected machinery operation. The Lock Box's lockout kits serve as an essential arsenal in this preventive strategy, offering a variety of lockout devices to suit different energy sources and machinery types.

Compliance with Safety Regulations

The adoption of LOTO procedures transcends operational safety, extending into the realm of regulatory compliance. Various international and local regulations mandate the implementation of effective energy control protocols, including LOTO, to protect workers from the hazards of uncontrolled energy releases. Adhering to these procedures not only upholds safety standards but also shields organizations from the legal consequences and financial liabilities associated with non-compliance. By following established LOTO protocols, companies demonstrate their commitment to regulatory adherence, thus avoiding potential penalties and reinforcing their reputation for safety and reliability.

Maintenance of Equipment Integrity

In the context of emergency shutdowns, the prompt and effective isolation of machinery and energy sources is paramount to avert exacerbation of the situation. LOTO procedures play a critical role in this context by ensuring that machinery is securely isolated from all energy sources. This isolation is crucial for facilitating a controlled and safe shutdown process, preventing further damage to the equipment, and minimizing the risk of secondary incidents. The application of LOTO in these scenarios helps in preserving the integrity of the equipment, ensuring that once the emergency is resolved, machinery can be safely brought back to operation with minimal downtime and repair needs.

Fostering a Safety Culture

The consistent integration of LOTO procedures into daily operations, maintenance routines, and emergency response plans cultivates a culture of safety within an organization. It underscores a clear organizational commitment to safeguarding the well-being of its workforce and the operational integrity of its machinery. This cultural shift towards safety consciousness elevates the overall safety standards, encourages proactive risk management, and instills a sense of shared responsibility among all employees. By embedding LOTO practices into the organizational fabric, companies not only enhance safety outcomes but also foster an environment where safety is viewed as a collective priority and a fundamental operational principle.

In essence, the role of LOTO in enhancing safety is multifaceted, addressing immediate risks while also contributing to long-term safety objectives. Through prevention, compliance, maintenance, and culture, LOTO establishes a comprehensive framework for managing and mitigating the risks associated with industrial operations, making it an indispensable component of workplace safety strategies.

The Lock Box: Your Partner in Safety

The Lock Box stands at the forefront of workplace safety, providing comprehensive LOTO solutions tailored to meet the needs of various industries. Our lockout kits and stations are designed with the end-user in mind, ensuring ease of use, durability, and compliance with safety standards.

Customized Solutions for Every Need

Understanding that every maintenance activity and emergency shutdown is unique, The Lock Box offers customizable solutions. Their products range from individual lockout devices to complete LOTO stations, ensuring that every organization can find the right fit for their specific needs.

Expert Support and Guidance

Beyond providing top-quality LOTO tools, The Lock Box also offers expert support and guidance to organizations looking to integrate or enhance their LOTO procedures. Their team of safety experts is available to assist with product selection, procedure development, and training, ensuring that organizations are fully equipped to implement effective LOTO procedures.