Introduction to Lockout Devices

In the industrial sector, it is crucial that machines and equipment are operated safely. One important measure to ensure this is the use of safe lockout devices, which prevent employees from coming into contact with hazardous machine parts or being accidentally present in a running machine. In this document, we will take a closer look at the various types of lockout devices and how they can be used effectively.

What Are Lockout Devices?

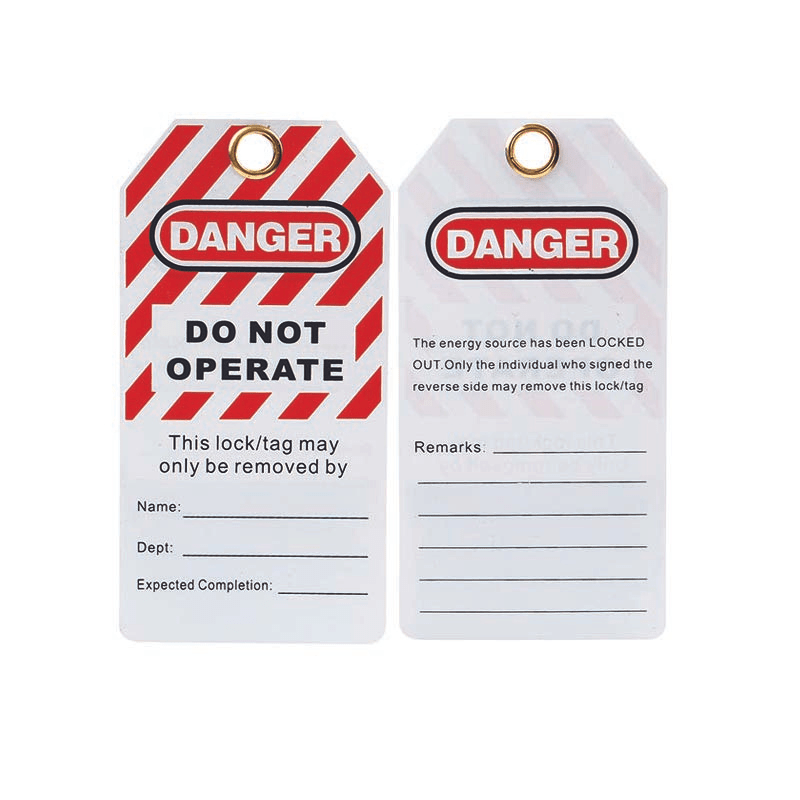

Lockout devices are special safety measures used to safely shut down and secure machines or equipment. The lockout tagout tryout procedure ensures that employees do not unintentionally come into contact with dangerous parts or be present in a running machine. Lockout devices can come in the form of lockout systems, locks, or clamps and are often used in conjunction with warning signs to indicate potential hazards.

Types of Lockout Devices

There are various types of lockout devices that can be selected depending on the type of machine or equipment and the specific safety requirements. Some common types of lockout devices include:

- Lockout systems: These devices and locks allow an authorized employee to attach a lock or key to a machine to protect it from unauthorized access.

- Clamps: These devices are used to hold movable machine parts in a specific position to prevent accidental start-up.

- Locks: Locks can be attached to control panels or operator panels to ensure they cannot be operated accidentally.

- Valve locks: These special locks are used to secure valves and control the movement of liquids or gases.

It is important to choose the right type of lockout device for each machine or piece of equipment and to ensure that all employees are trained on how to properly use them.

Lockout-Tagout Procedures

Lockout-Tagout is a safety procedure used in conjunction with lockout devices to ensure that machines and equipment are properly secured. It includes the following steps:

- Preparation: Identify all energy sources of the machine or equipment and determine which lockout devices are needed.

- Shutdown: Turn off the machine or equipment and disconnect it from all energy sources.

- Application: Attach the selected lockout devices to the appropriate points to ensure that the machine or equipment cannot be accidentally turned on.

- Verification: Carefully check that all energy sources of the machine or equipment are actually turned off.

- Release: Once the work is complete, remove the lockout devices and ensure that all employees are outside the danger zones.

Lockout-Tagout procedures are essential for preventing accidents and injuries. It is important that all employees understand and strictly follow the procedures to ensure their safety in the workplace.

Training and Monitoring

Compliance with Lockout-Tagout procedures requires thorough training of employees. All employees should be trained on how to properly use lockout devices and how to safely secure machines or equipment.

In addition, it is important to conduct regular monitoring to ensure that the procedures are being followed correctly. This can be done through regular inspections of the lockout devices and checking for compliance with safety protocols.

Liability

Compliance with Lockout-Tagout procedures is not only important for employee safety but also for employer liability. If an accident occurs due to missing or improperly applied lockout devices, legal consequences may follow. Therefore, it is important for companies to ensure that all employees are trained and that the procedures are strictly followed.

Conclusion: Lockout-Tagout Devices

Adherence to Lockout-Tagout procedures is critical for workplace safety. Through thorough training, monitoring, and liability responsibility, accidents and injuries can be prevented. It is the responsibility of every employee to know and follow these procedures to ensure a safe working environment for themselves and their colleagues. Regular training and reviews of the procedures should also be conducted to ensure that all employees are up to date and following safe work practices. As long as all parties work together and take the procedures seriously, a safe working environment can be achieved.

Additional Resources

- OSHA Guide for Lockout-Tagout

- National Institute for Occupational Safety and Health (NIOSH) - Recommendations for Avoiding Hazards During Maintenance

- Lockout-Tagout Training Videos

- Toolbox Talks on Workplace Safety

Ensuring that all employees are familiar with the procedures and apply them correctly is crucial. Investing in safe work practices and compliance with Lockout-Tagout procedures can prevent accidents and improve employee well-being. It is important to regularly discuss these topics and emphasize the importance of procedure compliance to ensure that everyone is working in a safe environment. Together, we can create a positive safety culture and reduce the number of workplace accidents.

Contact us for support with system maintenance and ensuring compliance with Lockout-Tagout procedures. We are here to help you create a safe and compliant working environment in your company.