Table of Contents

Every minute your team spends chasing a signature on a paper permit is a minute of lost production. How much is that costing you per year? For many companies, the answer is staggering. The move to a digital permit-to-work system isn't just about going paperless; it's a direct investment in your facility's efficiency, safety, and bottom line.

Within the hyper-competitive manufacturing landscape, every second counts. Companies are under immense pressure to increase output, reduce costs, and maintain a safe working environment. They face numerous challenges, from supply chain disruptions and skilled labor shortages to ever-increasing regulatory scrutiny. In this environment, clinging to outdated, paper-based processes is not just inefficient; it's a risk to operations.

This is where a digital permit-to-work system comes in. By digitizing and automating the entire permit-to-work process—from request and approval to closure and auditing—companies can unlock a host of benefits that go far beyond simply eliminating paper. They can slash downtime, improve compliance, and gain a significant competitive advantage.

The Hidden Costs of an Analog System

The tangible and intangible costs of a paper-based permit system can be a significant drain on resources. These costs can be broken down into three main categories:

1. The Crippling Cost of Downtime

Unplanned downtime is a silent killer of profitability in the manufacturing industry. It's the time when machines are not running, production lines are at a standstill, and revenue is taking a nosedive. The costs associated with downtime are multifaceted and can quickly spiral out of control.

A 2023 survey commissioned by ABB, titled the "Value of Reliability," revealed that unplanned downtime costs industrial businesses a median of nearly $125,000 per hour. For a medium-sized facility, even a fraction of that can be devastating. For example, if your facility's downtime costs a more conservative $5,000 per hour and you can save just 30 minutes per day on permit delays, that's over $60,000 in recovered production annually.

The costs of downtime go far beyond just lost production. Consider the ripple effects:

- Reputational Damage: Missed deadlines and delayed shipments can damage your reputation and erode customer trust.

- Expedited Shipping Costs: To make up for lost time, you may have to resort to expensive expedited shipping options.

- Wasted Labor: When your machines are down, your operators are idle, but you're still paying their wages.

- Increased Stress and Frustration: Downtime creates a high-stress environment for everyone, from the plant floor to the executive suite.

A paper-based permit system is a major contributor to unplanned downtime. The "walk-and-wait" nature of the process, where permits have to be physically carried from one person to another for approval, is inherently slow and inefficient. A simple delay in getting a signature can cascade into a major production issue, bringing your entire operation to a halt.

2. The Inefficiency of Wasted Labor

Your skilled technicians and engineers are your most valuable assets. They are the ones who keep your machines running, your processes optimized, and your products flowing out the door. Why are they spending so much of their time on non-value-added administrative tasks?

With a paper-based permit system, a significant portion of their day is consumed by "walk-and-wait" activities:

- Searching for Approvers: A permit can require multiple signatures, and tracking down the right people can be a time-consuming and frustrating process.

- Deciphering Illegible Handwriting: Poor handwriting can lead to confusion, errors, and delays.

- Dealing with Lost or Damaged Permits: Paper permits are easily lost, misplaced, or damaged, which can bring the entire work order to a standstill.

- Manual Data Entry: Information from paper permits often has to be manually entered into other systems, which is a tedious and error-prone process.

This wasted labor is a direct hit to your operational efficiency. It's time that your skilled technicians and engineers could be spending on more important tasks, such as preventative maintenance, process improvement, and innovation. Furthermore, it has a negative impact on employee morale. No one wants to spend their day chasing paperwork.

3. The High Stakes of Non-Compliance

In the manufacturing industry, safety is paramount. Failure to comply with Occupational Safety and Health Administration (OSHA) regulations in the U.S., or similar regulations in Europe, can have serious consequences, including hefty fines and legal action. A paper-based permit system makes it incredibly difficult to ensure compliance and can leave you exposed to significant risk.

Preparing for an audit with a paper-based system is a challenge. It involves manually sifting through filing cabinets and binders to produce the required documentation. It's a time-consuming, labor-intensive, and error-prone process. If you can't produce the right documentation, you could be facing serious penalties.

As an example, the official penalty amounts published by the U.S. Department of Labor for 2025 show that OSHA fines for non-compliance are higher than ever:

- Serious Violations: Up to $16,550 per violation

- Willful or Repeated Violations: Up to $165,514 per violation

The costs of non-compliance go beyond just fines. A serious safety incident can have a devastating impact on your company's reputation, your brand image, and your ability to attract and retain talent.

The ROI of Going Digital

A digital permit-to-work system is the engine for efficiency that directly addresses these hidden costs. By digitizing and automating the entire permit-to-work process, a digital system can help you slash downtime, improve compliance, and unlock a host of other benefits.

1. Instantaneous Approvals

With a mobile-first platform, permit requests and approvals can be managed from anywhere, at any time. What used to take hours of walking and waiting can now be accomplished in seconds.

Imagine this scenario: A technician on the plant floor needs to perform a critical repair. With a paper-based system, they would have to fill out a permit, track down their supervisor for a signature, and then take the permit to the safety manager for final approval. This process could take hours, during which time the machine is down and production is at a standstill.

With a digital system, the technician can submit the permit request from their mobile device. The supervisor and safety manager are instantly notified and can review and approve the permit in seconds, no matter where they are. The machine is back up and running in a fraction of the time, and a major production delay has been averted.

2. Audit-Ready, Instantly

With a digital system, all of your permit data is stored in a centralized, secure, and easily searchable database. This means that you are always audit-ready.

When an auditor arrives, you can simply log into the system and generate a complete audit trail for any time period with just a few clicks. No more digging through filing cabinets, no more searching for lost permits, and no more stress.

The benefits of a centralized data repository go beyond just audit preparedness. You can also use the data to identify trends, track key performance indicators (KPIs), and make more informed decisions about safety and operations.

3. Standardization = Speed and Quality

Digital templates and required fields ensure that every permit is filled out correctly and completely the first time. This eliminates errors, guesswork, and the back-and-forth that comes with incomplete or illegible paper forms.

You can also create custom checklists and workflows to ensure that all safety procedures are followed correctly for every job. This not only improves the quality and consistency of your permits but also helps to create a stronger safety culture throughout your organization.

4. Data-Driven Insights

A digital permit-to-work system is not just about streamlining workflows; it's about generating valuable data. This data can be analyzed to identify recurring delays, common hazards, and other operational bottlenecks, allowing for continuous improvement and a proactive approach to safety and efficiency.

For example, you can use the data to:

- Identify the most common reasons for permit delays and take action to address them.

- Track the number of incidents and near-misses and identify areas for improvement.

- Monitor the performance of your safety procedures and make adjustments as needed.

- Identify leading indicators of incidents and take proactive steps to prevent them from happening.

By harnessing the power of data, you can move from a reactive to a proactive approach to safety and operations, driving continuous improvement and creating a safer, more efficient, and more profitable workplace.

A Simple Calculation

Curious about your potential savings? Try using this simple formula below.

(Avg. Permit Delay in Hours) x (Number of Permits per Day) x (Cost of Downtime per Hour) = Your Potential Savings

Conclusion

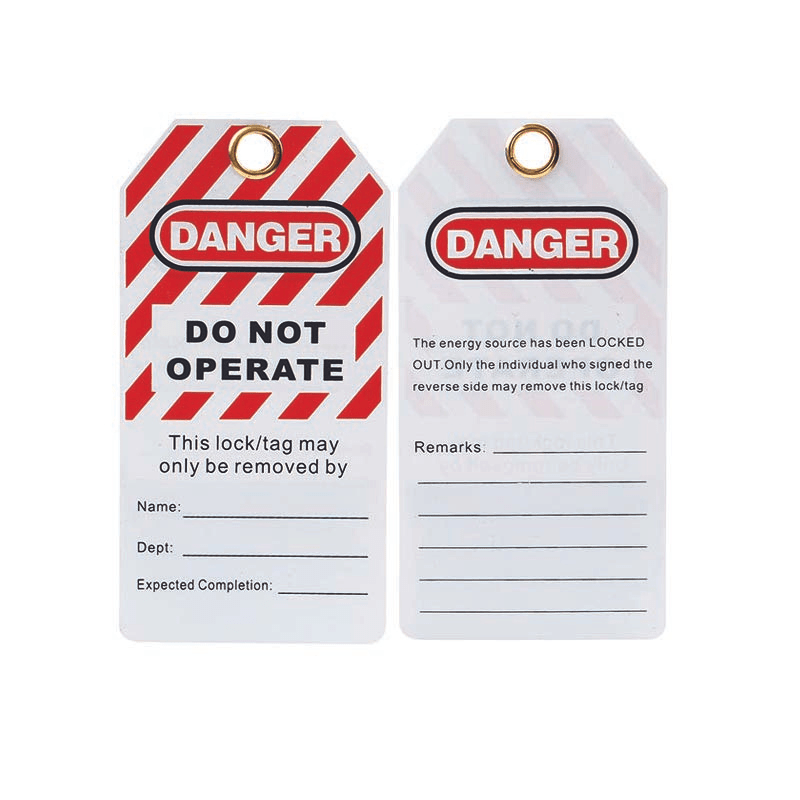

In the competitive manufacturing landscape, companies cannot afford to be held back by outdated, paper-based processes. A digital permit-to-work system like Zentri offers a clear and compelling ROI by reclaiming lost time, strengthening compliance, and creating a safer work environment. By connecting your permit process directly to your LOTO procedures and kits, Zentri closes a critical safety gap that standalone systems leave wide open.

Ready to stop wasting time and money?

Visit www.zentri.cc to schedule a demo and see how you can calculate your company's specific ROI.