A systematic approach to workplace safety is not just a regulatory requirement; it's a cornerstone of a productive, reliable, and responsible business. This guide offers a straightforward methodology for conducting risk assessments, helping you protect your personnel and operations.

Table of Contents

- 1. Introduction to Workplace Safety Risk Assessments

- 2. Why Are Workplace Safety Risk Assessments Crucial?

- 3. The Four-Step Methodology for Effective Risk Assessments

- 4. Risk Assessment: The Foundation of Site Safety

- 5. Integrating Lockout Tagout (LOTO) and Safety Signage

- 6. Conclusion: Upholding Safety Standards

1. Introduction to Workplace Safety Risk Assessments

A workplace safety risk assessment is a fundamental process in maintaining a safe and healthy work environment. It involves a careful examination of what in your workplace could cause harm to people, so you can weigh up whether you have taken enough precautions or should do more to prevent harm. The aim is to identify potential hazards and evaluate the risks associated with them, then implement measures to eliminate or control these risks. For industries ranging from construction and manufacturing to pharmaceuticals and electrical services, a robust risk assessment process is indispensable. It forms the backbone of effective safety management, ensuring that safety isn't left to chance but is instead a structured and ongoing effort. This proactive stance not only safeguards employees but also enhances operational efficiency and upholds a company’s reputation.

2. Why Are Workplace Safety Risk Assessments Crucial?

Conducting thorough workplace safety risk assessments is not merely a bureaucratic exercise; it’s an essential practice with far-reaching benefits.

Legal Obligations

Across Europe, including Switzerland, businesses are legally mandated to ensure the health and safety of their employees. European safety regulations, such as Framework Directive 89/391/EEC, oblige employers to evaluate workplace risks and implement preventive measures. Non-compliance can lead to severe penalties, including fines and legal action. A systematic risk assessment is the first step towards meeting these legal requirements.

Preventing Accidents and Injuries

The primary goal of a risk assessment is to prevent workplace accidents, injuries, and occupational illnesses. By identifying hazards and mitigating the associated risks, companies can significantly reduce the incidence of harm to their workforce. This proactive approach is far more effective and less costly than reacting to incidents after they occur.

Protecting Assets and Reputation

Workplace incidents can lead to damaged equipment, lost production time, and increased insurance premiums. Beyond the financial costs, accidents can severely damage a company's reputation among employees, customers, and the wider community. A commitment to safety, demonstrated through diligent risk assessment, helps protect these valuable assets.

Improving Productivity and Morale

A safe workplace is a productive workplace. When employees feel safe and valued, their morale and engagement are higher. Fewer disruptions from accidents mean smoother operations. Moreover, the process of risk assessment itself can lead to improvements in work processes and efficiency as potential issues are identified and addressed.

3. The Four-Step Methodology for Effective Risk Assessments

A structured approach ensures that risk assessments are thorough, consistent, and effective. The following four-step methodology provides a clear framework for any organisation.

3.1 Step 1: Identify Hazards

The first stage is to systematically identify all potential hazards within the workplace. A hazard is anything with the potential to cause harm. These can be categorized as:

- Physical hazards: Slips, trips, falls, working at height, machinery, noise, vibration, radiation, extreme temperatures. In industries like construction, unguarded machinery or unstable structures are common physical hazards.

- Chemical hazards: Exposure to harmful substances, liquids, fumes, dusts, or gases. Pharmaceutical and manufacturing sectors often handle a variety of chemicals that require careful management.

- Biological hazards: Bacteria, viruses, fungi, and other microorganisms. Relevant in healthcare, laboratories, and sometimes in agricultural settings.

- Ergonomic hazards: Poorly designed workstations, repetitive tasks, manual handling, awkward postures. These can lead to musculoskeletal disorders over time.

- Psychosocial hazards: Stress, bullying, harassment, violence, work overload. These affect mental well-being and can contribute to physical health problems.

- Electrical hazards: Exposed wires, faulty equipment, improper grounding. A major concern in electrical work and many manufacturing environments.

Methods for hazard identification include:

- Workplace inspections: Regularly walking through the workplace to spot potential issues.

- Incident reports: Analysing past accidents and near-misses to identify recurring hazards.

- Employee consultation: Workers often have firsthand knowledge of hazards associated with their tasks. Engaging them in the process is crucial.

- Task analysis (Job Safety Analysis - JSA): Breaking down jobs into individual tasks to identify hazards at each step.

- Reviewing manufacturer’s instructions for equipment and data sheets for chemicals.

Consider the specific environment. For example, in a manufacturing plant, hazards might include moving parts of machinery, high noise levels, or chemical exposure. On a construction site, falling objects, working at height, and excavation collapses are key concerns.

3.2 Step 2: Assess Risks

Once hazards are identified, the next step is to assess the risk associated with each one. Risk is the likelihood of a hazard causing harm, combined with the severity of that harm.

Likelihood: How probable is it that the hazard will result in an incident? This can be rated qualitatively (e.g., very likely, likely, unlikely, very unlikely) or quantitatively (e.g., based on frequency data).

Severity: If an incident occurs, what would be the extent of the harm? This can range from minor injuries (e.g., small cuts, bruises) to major injuries (e.g., fractures, amputations), long-term health issues, or even fatalities.

A common tool for risk assessment is a risk matrix. This typically plots likelihood against severity to assign a risk level (e.g., high, medium, low). For example:

- A hazard that is very likely to occur and could cause severe harm would be classified as a high risk.

- A hazard that is unlikely to occur and would cause minor harm would be a low risk.

This process helps to prioritize which risks need the most urgent attention. High-risk hazards require immediate action to implement control measures. Medium risks should be addressed in a planned manner, while low risks may require monitoring and minor controls.

3.3 Step 3: Implement Control Measures

After identifying hazards and assessing their risks, the next critical step is to implement measures to eliminate or control these risks. The widely accepted "Hierarchy of Controls" provides a framework for selecting the most effective control measures, in order of preference:

- Elimination: Physically remove the hazard. For example, discontinue the use of a hazardous chemical or a dangerous piece of equipment. This is the most effective control.

- Substitution: Replace the hazard with a less hazardous alternative. For example, using a less toxic solvent or a machine with lower noise emissions.

-

Engineering Controls: Isolate people from the hazard or modify the hazard source. This includes installing machine guards, ventilation systems, or modifying tools and equipment.

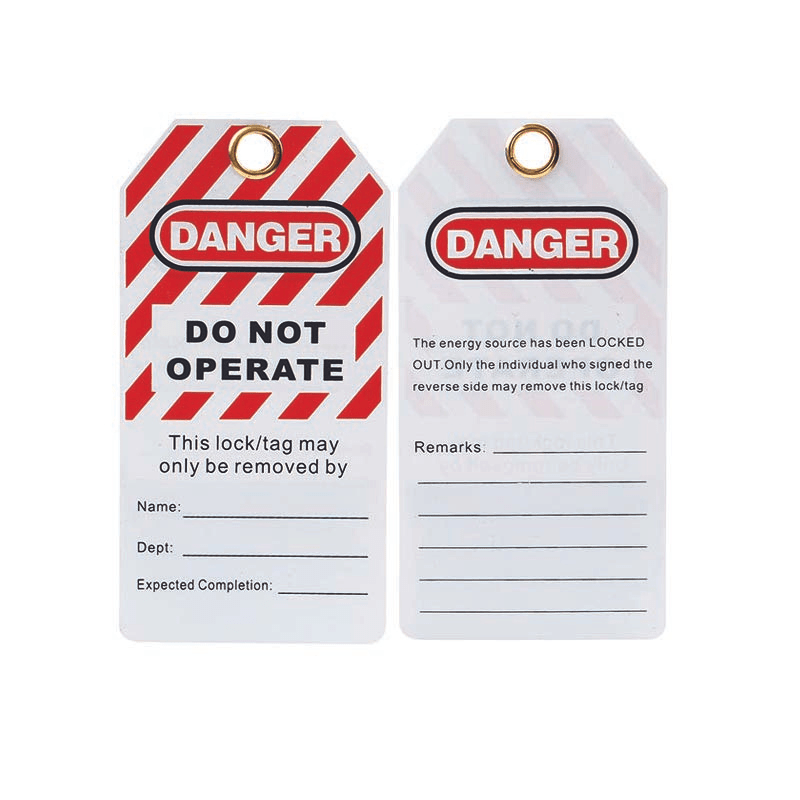

- Lockout Tagout (LOTO) procedures are a prime example of an engineering and administrative control. When machinery or equipment needs servicing or maintenance, LOTO ensures that hazardous energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) are properly isolated and rendered inoperative. The Lock Box offers a comprehensive range of Padlocks, Lockout Kits, and specific devices such as Valve Lockout Devices and Electrical Lockout Devices to effectively manage these risks. For instance, our Ball Valve Lockouts or Gate/Globe Valve Lockouts prevent accidental activation of valves during maintenance. Similarly, Circuit Breaker Lockouts and Pneumatic Lockouts are essential for isolating energy sources.

-

Administrative Controls: Change the way people work. This includes implementing safe work procedures, training, job rotation to reduce exposure, and supervision.

- Safety Signage plays a crucial role here. Clear, concise, and compliant Safety Signage warns employees of hazards, provides instructions, and indicates the location of safety equipment. This includes prohibition signs, warning signs, mandatory action signs, and emergency escape or first-aid signs. The Lock Box provides a wide array of signage solutions to meet diverse industrial needs.

- Lockout Tagout procedures also heavily rely on administrative controls, including the proper use of Lockout Tagout Tags to communicate that a device is isolated and should not be operated.

- Personal Protective Equipment (PPE): Protect the worker with PPE such as safety glasses, gloves, respirators, hard hats, and safety footwear. PPE should be considered the last line of defence, used when other controls are not feasible or to supplement existing controls.

When selecting controls, always aim to address the risk with the highest-level control measure possible. Often, a combination of controls will be necessary to adequately reduce risk. For complex operations, tools like Lockboxes (Group Lockout Boxes) facilitate safe LOTO procedures involving multiple workers and energy sources.

3.4 Step 4: Review and Update

Workplace safety is not a one-time task; it's an ongoing process. Therefore, risk assessments must be regularly reviewed and updated to ensure they remain relevant and effective.

A review should be conducted:

- At planned intervals: For example, annually, or as determined by your organisation’s safety management system.

- After an incident or near-miss: To identify any failings in the existing assessment or control measures.

- When there are significant changes in the workplace: This includes new machinery, new substances, changes in work processes, new personnel, or new information about hazards.

- Following changes in legislation or standards: To ensure ongoing compliance.

The review process should involve checking if the implemented control measures are working as intended, if any new hazards have emerged, and if the risk assessment still accurately reflects the workplace environment. Employee feedback is invaluable during this stage.

Documentation is a key part of the risk assessment process. Keep records of your risk assessments, including the hazards identified, risks assessed, control measures implemented, and details of reviews. This documentation demonstrates compliance and provides a valuable resource for future assessments and safety training. Well-organized Lockout Tagout Stations or Shadowboards can also help in maintaining and visually managing LOTO devices, contributing to an organised review process.

This commitment to continuous improvement is vital for maintaining a safe workplace and adapting to evolving operational needs and regulatory landscapes.

4. Risk Assessment: The Foundation of Site Safety

A proactive and systematic approach to risk assessment is the bedrock upon which a strong safety culture is built. It moves safety from a reactive, incident-driven concern to a proactive, preventative strategy. When organisations prioritize understanding and mitigating potential dangers, they are not just ticking boxes for compliance; they are actively fostering an environment where safety is integral to every operation.

This foundational role of risk assessment impacts several key areas:

- Informed Decision-Making: Risk assessments provide the necessary data for making informed decisions about safety investments, resource allocation, and operational procedures. Instead of guessing where dangers lie, decisions are based on identified hazards and assessed risks.

- Enhanced Safety Awareness: The process of conducting risk assessments, especially when it involves employee participation, raises overall safety awareness across the organisation. Employees become more attuned to potential hazards in their daily tasks.

- Resource Prioritization: Not all risks are equal. Risk assessments allow businesses to prioritize their efforts and resources on the most significant risks, ensuring that the most critical dangers are addressed first and most effectively.

- Legal and Regulatory Compliance: As mentioned, comprehensive risk assessments are a legal requirement in many jurisdictions. Fulfilling this requirement is fundamental to avoiding penalties and demonstrating due diligence.

- Building a Safety Culture: When management visibly commits to the risk assessment process and acts on its findings, it sends a powerful message that safety is valued. This commitment, coupled with employee involvement, helps to embed safety into the company culture, making it 'the way we do things around here.'

The effectiveness of the entire safety management system hinges on the quality and thoroughness of the initial risk assessments. Without a clear understanding of the hazards and risks, subsequent safety efforts, including training, procedures, and the provision of safety equipment, may be misdirected or insufficient.

5. Integrating Lockout Tagout (LOTO)

The insights gained from a thorough risk assessment directly inform the need for specific safety interventions, such as Lockout Tagout (LOTO) procedures and the strategic use of Safety Signage. These are not standalone solutions but integral components of the control measures identified during Step 3 of the risk assessment process.

Lockout Tagout (LOTO) as a Critical Control

During a risk assessment, any task involving machinery or equipment maintenance, repair, servicing, or cleaning will likely identify hazardous energy as a significant risk. This includes electrical, mechanical, hydraulic, pneumatic, chemical, or thermal energy. Accidental start-up or release of stored energy during such tasks can lead to severe injuries or fatalities.

In these scenarios, LOTO procedures become an essential control measure. The risk assessment will highlight:

- Which machines or equipment require LOTO.

- The types of energy sources that need to be isolated.

- The specific procedures for isolating, locking, and tagging these sources.

- The personnel authorized and trained to perform LOTO.

The Lock Box provides a comprehensive suite of LOTO solutions tailored to various industrial needs. From individual Padlocks and tags to complex Cable Lockouts for isolating multiple energy points, or specialized devices for Valve Lockouts (e.g., Ball Valve, Gate/Globe Valve, Butterfly Valve lockouts) and Electrical Lockout Devices (e.g., Circuit Breaker Lockouts, Miniature Circuit Breaker Lockouts, Switch Lockouts), our products are designed to ensure hazardous energy is effectively controlled. For team operations, Lockboxes and Hasps allow multiple workers to apply their personal locks. Complete Lockout Kits provide a convenient way to equip teams with necessary LOTO devices.

By integrating LOTO and Safety Signage as direct outcomes of the risk assessment process, companies can create a multi-layered defence against workplace hazards, significantly enhancing overall site safety.

6. Conclusion: Upholding Safety Standards

Conducting effective workplace safety risk assessments is not just a regulatory hurdle but a fundamental business practice that protects your most valuable asset—your people—and safeguards your operations. The four-step process of identifying hazards, assessing risks, implementing controls, and reviewing the assessment provides a robust framework for managing workplace safety proactively.

This systematic approach, reflecting the Swiss principles of precision and quality that The Lock Box stands for, naturally leads to the identification of necessary control measures. Many of these controls will involve the implementation of thorough Lockout Tagout procedures and the strategic placement of clear Safety Signage.

The Lock Box is committed to supporting your safety efforts by providing a comprehensive range of high-quality LOTO devices, safety signs, and organisational tools. We encourage all businesses to embrace a diligent risk assessment culture, ensuring a safer and more productive environment for everyone. By understanding and mitigating risks, you are not only complying with European safety regulations but also investing in the long-term success and resilience of your organisation.