Table of Contents

- Introduction: Why Digitize Your LOTO Procedures?

- Step 1: Assess Your Current LOTO Landscape

- Step 2: Build Your Team and Secure Buy-In

- Step 3: Define Your Requirements and Choose the Right Software

- Step 4: Plan and Execute the Migration

- Step 5: Train, Deploy, and Continuously Improve

- Conclusion: Taking Control of Your Safety Procedures

Introduction: Why Digitize Your LOTO Procedures?

Transitioning from a paper-based Lockout Tagout (LOTO) system to a digital one can seem like a monumental task. Yet, the move from cluttered binders and manual audits to a streamlined, digital workflow is not just an upgrade—it's a fundamental transformation of a critical safety process. For industries where hazardous energy is a daily reality, this shift is about enhancing safety, ensuring compliance, and boosting operational efficiency. A digital system provides real-time visibility, standardizes procedures across multiple sites, and simplifies the auditing process, turning a cumbersome administrative task into a dynamic safety tool. This guide offers a clear, five-step roadmap for any company ready to move from the chaos of paper-based systems to the control of a digital LOTO solution.

Step 1: Assess Your Current LOTO Landscape

Before you can move forward, you must have a comprehensive understanding of where you currently stand. A thorough assessment of your existing LOTO program is the foundation of a successful digital transition. This involves more than just acknowledging you use paper; it requires a deep dive into the specifics of your procedures, their effectiveness, and their shortcomings.

Conduct a Thorough Audit

Start by auditing your current LOTO procedures. This audit should cover:

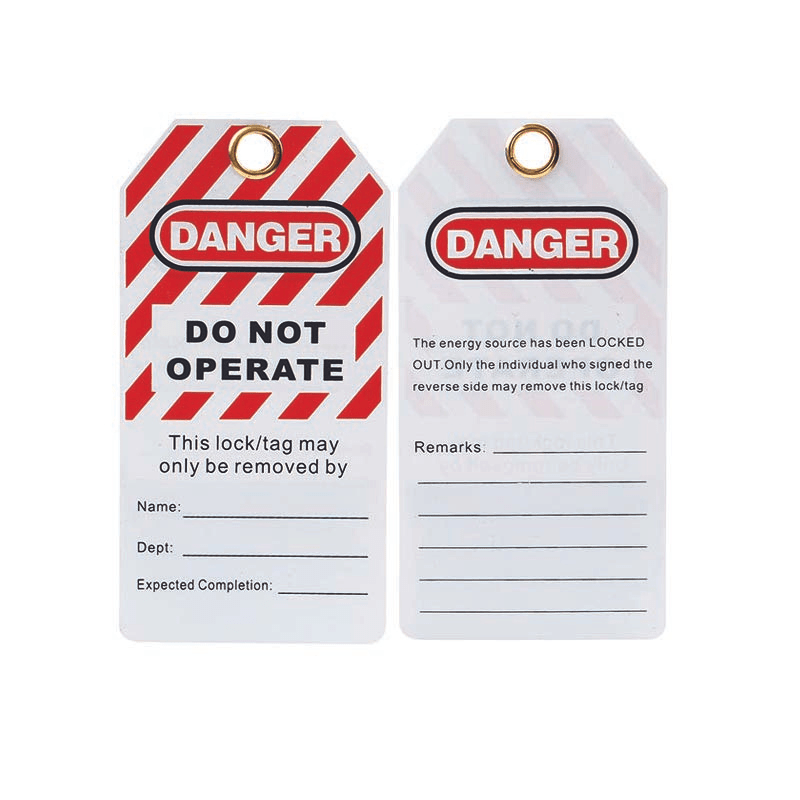

- Procedure Documentation: Are your procedures well-documented, clear, and easily accessible? Are they specific to each piece of equipment? Collect examples of all your current LOTO documents, from tags and forms to equipment-specific procedures.

- Employee Knowledge: Interview the employees and supervisors who use the LOTO system daily. Do they understand the procedures? Are they following them consistently? Identify any gaps in knowledge or adherence.

- Compliance: How do your current practices measure up against relevant regulations, such as OSHA 29 CFR 1910.147 in the United States or the European Union's Directive 89/655/EEC? Note any areas of non-compliance or potential risk.

- Efficiency: How much time is spent on LOTO-related paperwork? How long does it take to perform a lockout, conduct an audit, or train a new employee? Quantify the administrative burden of your current system.

Identify Pain Points

Based on your audit, identify the specific pain points of your paper-based system. These might include:

- Inconsistent application of procedures across different shifts or departments.

- Difficulty in tracking and managing lockout devices like Cadenas de Consignation (Padlocks) or Crochet de Consignation (Hasps).

- Time-consuming and error-prone annual audits.

- Lost or damaged procedure documents.

- Lack of visibility into ongoing lockout activities for management.

Understanding these challenges will not only build the case for digitalization but will also help you define what you need from a new system.

Step 2: Build Your Team and Secure Buy-In

A digital transformation is as much about people as it is about technology. Without support from both management and the employees who will use the system, even the best software will fail. Gaining buy-in is a universal challenge that requires a clear communication strategy.

Form a Cross-Functional Team

Assemble a project team that includes representatives from every stakeholder group:

- Safety Managers: They will own the project and be responsible for its overall success.

- Frontline Employees (Authorized and Affected): Their input is invaluable for ensuring the new system is practical and user-friendly.

- Maintenance Staff: As frequent users of LOTO, their perspective on usability is critical.

- IT Department: They will be essential for assessing software compatibility, security, and integration with existing systems.

- Management/Leadership: A champion in a leadership position is crucial for securing resources and driving the project forward.

Communicate the "Why"

To get buy-in, you need to articulate the benefits of digitalization for each group:

- For Management: Frame the change in terms of ROI. Highlight enhanced compliance, reduced risk of fines, increased operational efficiency (less downtime), and better data for decision-making. Present the findings from your Step 1 audit to underscore the costs and risks of the current system.

- For Employees: Focus on safety and simplicity. Emphasize that a digital system makes their job easier and safer. Digital guides with images and clear steps on a mobile device are far more accessible than a binder in a control room. Assure them that this is a tool to empower them, not to micromanage them. Address concerns about technology being difficult to use by promising comprehensive training and support.

Hold town hall meetings, create informational materials, and provide opportunities for open discussion to address concerns and build enthusiasm for the project.

Step 3: Define Your Requirements and Choose the Right Software

With a clear understanding of your current system's flaws and a team ready to embrace change, you can now define the features your new LOTO software must have. This is a critical step to ensure you select a solution that meets the unique needs of your operations, whether in a single country or across continents.

Key Features for a Global Audience

When evaluating LOTO software, prioritize functionalities that offer flexibility, accessibility, and robust compliance tools:

- Mobile Accessibility: For large facilities, common in the US, or for field teams, the ability to access procedures, apply locks, and complete checklists on a tablet or smartphone is non-negotiable. This eliminates the need to walk back and forth to a central station to retrieve paper documents.

- Multi-Language Support: For European teams operating across borders, the software must be available in multiple languages. This ensures that every employee, regardless of their native tongue, can clearly understand and follow critical safety procedures. The Lock Box understands this need, offering product information in English, French, and German. For example, a Lockout Tagout Tag is an Etiquette de condamnation in French and an Anhänger für Warnhinweise in German. The software should reflect this linguistic diversity.

- Customizable Templates: Regulations can vary. The software should allow you to create and customize LOTO procedures and LOTO Tags (tags) to meet any specific regulatory requirement, be it OSHA, EU directives, or internal company standards.

- Visual Procedure Guides: The ability to include photos and videos in procedures is a powerful tool. It reduces ambiguity and provides clear, step-by-step instructions for locking out complex equipment, from valve lockouts to circuit breakers.

- Reporting and Analytics: A key advantage of digital systems is data. The software should provide a dashboard with real-time insights into LOTO activities, audit trails, compliance reports, and performance metrics.

- Integration Capabilities: Consider how the software will work with your existing systems, such as your Enterprise Asset Management (EAM) or Computerized Maintenance Management System (CMMS).

Evaluate Vendors

Once you have your list of requirements, research and shortlist potential software vendors. Request demos, run trials with your project team, and check references. Don't just look at the software; assess the vendor's support, training, and implementation process.

Step 4: Plan and Execute the Migration

This is where the digital transformation truly begins. A phased approach is generally the most effective way to migrate from paper to a digital system, minimizing disruption and allowing for adjustments along the way.

Create a Phased Rollout Plan

Instead of a company-wide launch, consider a pilot program. Select a single department, area, or facility to be the first to transition. This allows you to test your process on a smaller scale, gather feedback, and resolve any issues before a full-scale deployment. Your plan should include:

- Data Migration: Digitize your existing equipment-specific procedures. This is often the most time-consuming part of the process. Allocate resources to photograph equipment isolation points and write clear, concise digital procedures. Many software vendors offer services to assist with this.

- Hardware Procurement: Ensure you have the necessary hardware, such as tablets or rugged mobile devices, for your employees.

- Timeline: Set a realistic timeline for each phase of the rollout, from the pilot program to the final deployment.

Establish Clear Workflows

Map out exactly how the digital LOTO process will work. Who creates and approves procedures? How does an employee initiate a lockout? How are verifications and shift handovers managed within the software? Define these workflows clearly to ensure consistency.

Step 5: Train, Deploy, and Continuously Improve

Successful deployment hinges on comprehensive training. Every employee who interacts with the LOTO system must be confident in using the new digital tools.

Conduct Role-Based Training

Different roles will use the software differently. Tailor your training accordingly:

- Authorized Employees: Focus on how to find procedures, apply and remove locks in the system, and conduct verifications.

- Supervisors and Managers: Train them on how to approve procedures, run reports, and manage LOTO activities.

- System Administrators: Provide in-depth training on configuring the software, managing users, and customizing templates.

Use a combination of classroom sessions, hands-on practice with the devices, and on-the-job support. Have your project team members act as "super users" who can provide immediate assistance to their peers.

Monitor and Gather Feedback

After deployment, the work isn't over. The goal is continuous improvement.

- Solicit Feedback: Regularly check in with users to understand what’s working well and what could be improved.

- Track Metrics: Use the software's analytics to monitor key performance indicators (KPIs) such as the number of lockouts performed, procedure usage, and audit completion rates.

- Refine and Update: Use the feedback and data you collect to refine your procedures, improve your training, and optimize your use of the software. A digital system makes it easy to update a procedure for a ball valve and instantly deploy it to all relevant personnel, ensuring everyone is always working with the most current information.

Conclusion: Taking Control of Your Safety Procedures

Moving from a paper-based LOTO system to a digital one is a significant undertaking, but the return on investment in terms of safety, compliance, and efficiency is undeniable. By following a structured, five-step approach—assessing your current state, securing buy-in, choosing the right tools, planning a phased migration, and committing to continuous improvement—any organization can successfully navigate this transition. A digital system turns chaotic paperwork into controlled, accessible, and actionable safety intelligence. From comprehensive Lockout-Tagout Sets (Lockout Kits) to specialized devices like Pneumatic Lockouts (Pneumatic Lockouts), the physical tools of safety are enhanced by a digital backbone that ensures they are used correctly, every single time. By embracing this change, you are not just modernizing a process; you are fostering a stronger, more resilient safety culture.