In the world of industrial safety, what you don't know can hurt you. Many facilities believe their Lockout Tagout (LOTO) procedures are robust and compliant, only to discover critical gaps during an audit or, worse, after an incident. These hidden risks often stem from outdated, manual processes that are prone to human error. This article exposes five common LOTO mistakes that could be undermining your safety program and introduces a powerful digital solution to fix them.

Table of Contents

- The Hidden Dangers of Traditional LOTO

- Mistake 1: Using Outdated Paper Procedures

- Mistake 2: Missing Equipment-Specific Steps

- Mistake 3: Poor Version Control

- Mistake 4: No Audit Trail of Execution

- The Digital Solution: A Before-and-After Workflow

- Take Control of Your Lockout Program with Zentri

The Hidden Dangers of Traditional LOTO

For Health, Safety, and Environment (HSE) officers, plant managers, and internal auditors, ensuring lockout tagout compliance is a top priority. The goal of LOTO is to protect workers from the unexpected energization or startup of machinery and equipment during service and maintenance. While most organizations have a LOTO program in place, many still rely on paper-based systems that are inefficient and fraught with potential for error.

These traditional methods often create a false sense of security. A binder full of procedures doesn't guarantee that the correct, most up-to-date information is being used in the field. This disconnect between documentation and execution is where the most dangerous safety procedure errors occur. The transition to a digital approach is no longer just an upgrade; it's a critical step in mitigating risk and fostering a culture of safety.

Mistake 1: Using Outdated Paper Procedures

One of the most prevalent LOTO mistakes is the reliance on paper-based procedures. These documents are often created and then filed away, rarely to be seen again until an audit. In a dynamic industrial environment, where machinery is updated and processes evolve, paper procedures quickly become obsolete.

An operator or maintenance technician might grab a procedure from a binder that hasn't been updated in years, leading them to follow steps that are no longer accurate or safe. This can result in missed energy sources, incorrect isolation points, or a failure to dissipate stored energy.

The Digital Fix with Zentri

A digital LOTO system like Zentri eliminates the problem of outdated paper trails. All LOTO procedures are stored in a centralized, cloud-based platform, ensuring that every employee has access to the most current version. When a procedure is updated, the changes are instantly reflected across the system, and all relevant personnel can be notified. This real-time access to accurate information is fundamental to a safe and compliant LOTO program.

Furthermore, digital procedures can be accessed on mobile devices, putting critical safety information directly in the hands of the workers who need it, right at the point of work. This eliminates the need for cumbersome binders and ensures that the right procedure is always used for the right task.

Mistake 2: Missing Equipment-Specific Steps

Generic LOTO procedures are a recipe for disaster. Different pieces of equipment have unique energy sources, isolation points, and shutdown sequences. A one-size-fits-all approach is not only non-compliant with regulations like OSHA 1910.147 but also dangerously inadequate.

Creating and maintaining equipment-specific procedures on paper can be a logistical nightmare, especially in a large facility with hundreds or thousands of machines. This often leads to shortcuts, where generic templates are used, or crucial details are omitted.

The Digital Fix with Zentri

Zentri's platform allows for the creation of detailed, equipment-specific LOTO procedures. You can upload photos, diagrams, and even videos to provide clear, unambiguous instructions for each isolation point. This visual approach helps to eliminate confusion and ensures that every energy source is accounted for.

By linking procedures to specific assets within the system, you can be certain that technicians are always using the correct, detailed instructions for the equipment they are servicing. This level of specificity is crucial for preventing accidents and ensuring lockout tagout compliance. To support these digital procedures, having the right physical equipment is essential. The Lock Box offers a comprehensive range of Valve Lockout Devices, Electrical Lockout Devices, and Pneumatic Lockouts to ensure every energy source can be securely isolated.

Mistake 3: Poor Version Control

In a paper-based system, how can you be sure that the procedure being used in the field is the most current version? Poor version control is a critical flaw in many traditional LOTO programs. When a procedure is updated, it can be a challenge to track down and replace all the old copies that might be floating around the facility.

This lack of control means that a well-intentioned employee could be following an outdated, and therefore unsafe, procedure without even realizing it. The potential for a serious incident in this scenario is unacceptably high.

The Digital Fix with Zentri

With a digital LOTO system, version control is automatic and foolproof. When a procedure is updated and approved in Zentri, the new version immediately becomes the only one accessible to users. The system maintains a complete history of all previous versions, providing a clear audit trail of who made what changes and when.

This centralized control eliminates the risk of outdated procedures being used and ensures that your entire organization is always working from the same, most current set of instructions. This not only improves safety but also simplifies compliance and reduces the administrative burden of managing LOTO documentation.

Mistake 4: No Audit Trail of Execution

Even with the best procedures, how can you be certain that they are being followed correctly every single time? A paper-based system offers no easy way to track the execution of LOTO procedures. Sign-off sheets can be lost, pencil-whipped, or filled out after the fact, providing little to no real assurance that the work was performed safely.

This lack of a verifiable audit trail is a major compliance gap and makes it incredibly difficult to investigate near misses or incidents. Without a clear record of who did what and when, it's challenging to identify root causes and implement effective corrective actions.

The Digital Fix with Zentri

Zentri provides a complete, time-stamped audit trail for every LOTO procedure. As employees complete each step, they can confirm their actions within the mobile app, creating a real-time record of the entire process. This digital "paper trail" is invaluable for accountability, compliance, and continuous improvement.

In the event of an audit, you can instantly generate reports that demonstrate not only that you have compliant procedures but also that they are being consistently followed in the field. This level of transparency is impossible to achieve with a paper-based system.

The Digital Solution: A Before-and-After Workflow

To illustrate the transformative impact of a digital LOTO system, let's look at a typical workflow before and after implementing a solution like Zentri.

Before: The Paper-Based Nightmare

- Find the Procedure: An employee needs to service a pump. They walk to a central office to find the LOTO procedure in a large, disorganized binder. They find a procedure for "pumps" but are unsure if it's the right one for this specific model.

- Gather Equipment: The employee gathers the necessary Padlocks and Hasps based on the generic procedure.

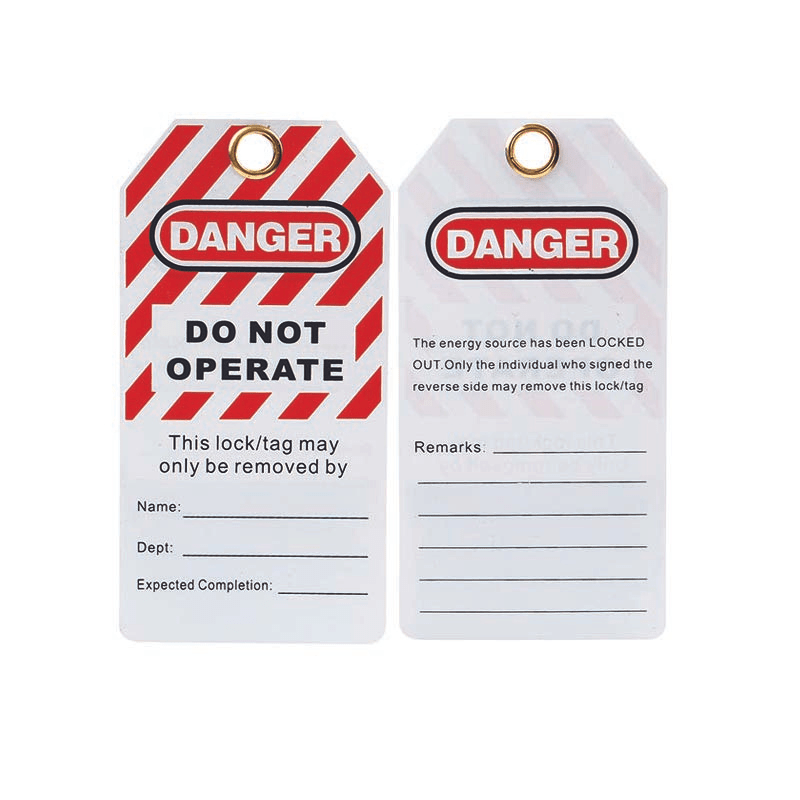

- Perform the Lockout: They follow the steps on the paper, hoping it's accurate. They sign a paper tag and hang it on the disconnect.

- Sign-off: After the work is complete, they sign a log sheet in the office, which is then filed away.

After: The Streamlined Zentri Workflow

- Access LOTO Plan: The employee loads Zentri, finds the relevant lockout tagout plan and selects it. The correct, equipment-specific LOTO procedure is available instantly.

- Guided Steps: The Zentri app can walk them through each step of the procedure, with clear instructions and images for each isolation point. They confirm the completion of each step in the app.

- Real-Time Tracking: The system logs every action, creating a complete, time-stamped audit trail. A supervisor can see the status of the lockout in real-time from their own device.

- Digital Sign-off: Once the work is complete and the equipment is safely re-energized, the employee completes the procedure in the app, and the audit trail is securely stored in the cloud.

Take Control of Your Lockout Program with Zentri

The risks associated with outdated, paper-based LOTO systems are too great to ignore. By embracing a digital LOTO system like Zentri, you can eliminate these common mistakes, improve lockout tagout compliance, and create a safer, more efficient work environment.

Don't wait for an audit or an incident to reveal the hidden gaps in your safety procedures. Take a proactive approach and empower your team with the tools they need to work safely and effectively.

Digitize your lockout program—start your free Zentri trial today.