The Ultimate Checklist for Laboratory Safety Showers: Ensuring Compliance and Safety

Table of Contents

- Introduction

- Why Labs Have Special Requirements for Safety Showers

- The Checklist: How to Select the Right Laboratory Safety Shower

- Placement is Critical: The 10-Second, Unobstructed Path Rule

- Our Recommendations: Proven HAWS Solutions for the Modern Lab

- Maintenance & Testing: Your Protocol for Guaranteed Readiness

- Conclusion

Imagine the scene: a routine procedure, a moment of distraction, a beaker slips. In an instant, a volatile chemical splashes. In this critical moment, the difference between a minor incident and a life-altering injury is measured in seconds. The immediate availability of an effective laboratory safety shower is the final, crucial line of defence in your facility's safety protocol.

This equipment is a fundamental component of the "Hierarchy of Controls," serving as an essential engineering control designed to mitigate the effects of an unavoidable exposure. But simply having a shower in the corner is not enough. Is it the right type for the chemicals you use? Is it installed correctly? Is it tested regularly and ready to perform flawlessly in an emergency?

This comprehensive guide is designed for anyone involved in lab safety—from EHS managers and facility engineers to procurement specialists and the technicians who rely on this equipment every day. We will go beyond the basics to provide a definitive checklist for selecting, placing, and maintaining the perfect safety solution for your lab, ensuring you meet strict compliance standards and, most importantly, uphold your commitment to personnel safety.

Why Labs Have Special Requirements for Safety Showers

Not all industrial safety showers are suited for the unique environment of a laboratory. A lab presents a distinct combination of hazards, spatial constraints, and personnel considerations that demand specialized equipment. In German-speaking Europe, this specialized unit is known as a Notdusche Labor, while in French-speaking regions, it's a douche de sécurité de laboratoire. Here’s why the details matter.

1. Advanced Chemical Resistance

A standard industrial shower might be exposed to dust or mild chemicals, but a lab shower must be prepared to handle everything from strong acids like sulfuric and hydrochloric acid, to aggressive bases like sodium hydroxide, and a vast array of organic solvents. The material of your safety shower must be compatible with these substances. Standard galvanized steel, for example, will quickly corrode. That's why premium lab showers are constructed from:

- Stainless Steel (Type 304 or 316): Offers excellent resistance to a wide range of chemicals and is easy to clean. Type 316 provides superior resistance to chlorides and acids.

- ABS Plastic: A durable, non-corrosive thermoplastic that is highly resistant to many chemicals and is often used for shower heads and eye wash bowls.

- Protective Coatings: High-quality powder coatings or epoxy finishes can provide an additional layer of protection for metal components.

2. Efficient Use of Limited Space

Laboratory floor space is a valuable commodity, meticulously planned for workflow and instrumentation. A bulky safety shower can obstruct pathways and create hazards. Lab-specific designs address this through:

- Combination Units: The gold standard for space efficiency, these units integrate a full-body drench shower and an eye/face wash station into a single plumbing fixture. This provides full protection without doubling the footprint.

- Mounting Options: Rather than only offering floor-mounted models, lab showers are available in wall-mounted configurations to keep the floor clear. For benches and sinks, deck-mounted or faucet-mounted eye wash units provide localized protection without consuming any floor space.

3. Controlled Water Flow and Tepid Water

In an emergency, the water from a safety shower must decontaminate, not inflict further harm. This is especially critical for the delicate tissues of the eyes.

- Controlled Flow: Older shower designs used simple nozzles that could spray water at an injurious pressure, potentially driving chemical contaminants deeper into the eye sockets. Modern, compliant systems like HAWS's AXION® MSR technology are engineered to deliver a gentle, laminar flow. For eye washes, the inverted stream flushes from the inside corner of the eye outwards, following medical protocols and preventing cross-contamination.

- Tepid Water: A full decontamination flush lasts for 15 minutes. If the water is too cold (below 16°C / 60°F), the victim may suffer hypothermia and be physically unable to complete the full flush. If it's too hot (above 38°C / 100°F), it can scald the victim and even accelerate the absorption of hazardous chemicals into the skin. Both EN and ANSI standards mandate the delivery of tepid water. This is usually achieved by installing a thermostatic mixing valve (TMV), a critical component that blends hot and cold water to a safe, consistent temperature.

The Checklist: How to Select the Right Laboratory Safety Shower

Follow this in-depth, three-step process to ensure you choose the most effective and compliant equipment for your facility.

Step 1: Conduct a Thorough Hazard and Risk Assessment

This is the most critical phase. Do not select a product until you have completed a formal assessment.

- Inventory Your Chemicals: Create a comprehensive list of all hazardous materials used in the lab.

- Consult Safety Data Sheets (SDS): For each chemical, review Section 4 (First-Aid Measures) and Section 8 (Exposure Controls/Personal Protection). These sections will often specify if an emergency eye wash or shower is required.

- Analyze Your Processes: Evaluate how personnel interact with these chemicals. Are they handling small vials or transferring large volumes? Are splashes likely to be localized (face/hands) or cover a large area of the body?

- Involve Your Team: Speak with the lab technicians and scientists. They have firsthand knowledge of the risks involved in their daily tasks. Their input is invaluable for identifying potential exposure points you might overlook.

Step 2: Determine the Right Type of Unit (In-depth Comparison)

Your risk assessment will now guide your product selection.

- Combination Showers: This is the default, go-to solution for almost any lab where full-body splash hazards exist. It consists of a drench shower activated by a rigid pull-rod and an eye/face wash basin activated by a push handle. The valve is designed to be "stay-open," freeing the user's hands to hold their eyes open or remove contaminated clothing.

- Standalone Eye/Face Wash Stations: These units, often referred to as a lave-yeux in French, are appropriate for areas where the only credible risk is a splash to the face.

- Plumbed Bowl Units: Wall- or pedestal-mounted units that provide a dedicated, reliable station.

- Faucet-Mounted Units: These attach to existing sinks and are a space-saving option for lower-risk areas, but they must not interfere with the normal operation of the faucet.

- Supplemental Equipment (Drench Hoses): These are flexible, hand-held spray hoses that can be used to rinse specific parts of the body. Important: Drench hoses are considered supplemental and do not replace the need for a proper, fixed eye wash or shower station.

Step 3: Verify Compliance with Key International Standards

Never assume a product is compliant. Demand certification and proof from the manufacturer. Your equipment must meet the standards relevant to your region.

-

EN 15154 (The European Standard):

- Flow Rate: Requires a minimum of 6 litres/minute for eye washes and specifies a "sufficient volume" for showers, generally interpreted from other norms as 60-100 L/min.

- Spray Pattern: Mandates a specific distribution and height for the water spray to ensure it covers the target area effectively.

- Valve Operation: Must activate in one second or less and stay open without the use of the operator's hands.

-

ANSI Z358.1-2014 (The Global Benchmark):

- Flow Rate: Mandates a minimum of 20 US gallons per minute (75.7 L/min) for showers and 0.4 GPM (1.5 L/min) for eye washes.

- Tepid Water: Explicitly requires water to be delivered in the 16-38°C (60-100°F) temperature range.

- Simultaneous Operation: If you have a combination unit, both the shower and the eye wash must be able to operate simultaneously, each meeting its respective performance requirements.

Reputable brands like Haws design their products to meet or exceed these stringent international standards, providing you with peace of mind.

Placement is Critical: The 10-Second, Unobstructed Path Rule

Where you install your douche de sécurité is just as important as which one you buy. A perfectly compliant shower that is difficult to reach is useless.

- The 10-Second Rule: A person who has been splashed, often in pain and with compromised vision, must be able to reach the unit within 10 seconds. This translates to a maximum travel distance of approximately 17 meters (55 feet). Use a stopwatch and walk the path from your highest-hazard areas to the proposed shower location.

- An Unobstructed Path: This is the most common point of failure in annual inspections. The path must be completely clear of any obstruction. This includes avoiding routes that require pushing open a door, stepping up or down a curb, or navigating around temporary storage carts. The path should be a straight line if at all possible.

- High Visibility and Clear Signage: The area must be well-lit. It must also be identified with a highly visible, universal safety sign (Piktogramm or pictogramme). The iconic green-and-white symbol should be mounted high enough to be seen over benches and equipment from all corners of the lab.

- Area Drainage: A 15-minute shower flush at 76 litres per minute will release over 1,100 litres (300 gallons) of water. You must have adequate floor drainage to handle this volume. Without it, you risk creating a massive secondary slip-and-fall hazard and potentially spreading chemical contaminants across the lab floor.

Our Recommendations: Proven HAWS Solutions for the Modern Lab

As a leading provider of safety equipment, we recommend HAWS products for their unmatched reliability, patented safety technology, and unwavering commitment to compliance.

Featured Model 1 (The All-Rounder): HAWS 8300-8309 Combination Shower

This series is a perfect example of a comprehensive Notdusche Labor.

- Best for: University chemistry labs, pharmaceutical R&D, and general-purpose industrial labs.

-

Key Features:

- Features the medically acclaimed AXION® MSR eye/face wash and showerhead for hydrodynamically superior performance that follows medical protocols.

- Available in durable stainless steel or corrosion-resistant powder-coated steel.

- Independently certified by CSA to meet both EN 15154 and ANSI Z358.1 standards.

[View Details & Request a Quote]

Featured Model 2 (The Space-Saver): HAWS 8320 Wall-Mounted Combination Unit

- Best for: Crowded labs, quality control areas, or facilities where floor space is at an absolute premium.

-

Key Features:

- Provides full combination-unit protection in a compact, off-the-floor design.

- Includes the same AXION MSR technology and stay-open valve as the larger pedestal models.

- Ideal for retrofitting into existing lab spaces with minimal disruption.

[View Details & Request a Quote]

While many facilities consider options like a Denios Augenduschen, the advanced hydrodynamic design of the HAWS AXION system offers a medically superior flush that is difficult to match—a critical factor when every second counts.

Maintenance & Testing: Your Protocol for Guaranteed Readiness

An untested safety shower is a liability waiting to happen. A regular, documented maintenance protocol is required by law and by common sense.

The Weekly Activation Protocol

Once a week, every single shower and eye wash must be activated.

- Prepare: Place a large bucket or run-off collector under the drain and put on safety glasses.

- Activate: Engage the valve long enough to verify flow and to flush any sediment or stagnant water from the "dead leg" portions of the pipe. This usually takes 1-3 minutes.

- Inspect: Visually check that the water is clear, the flow is steady, and the spray pattern is correct.

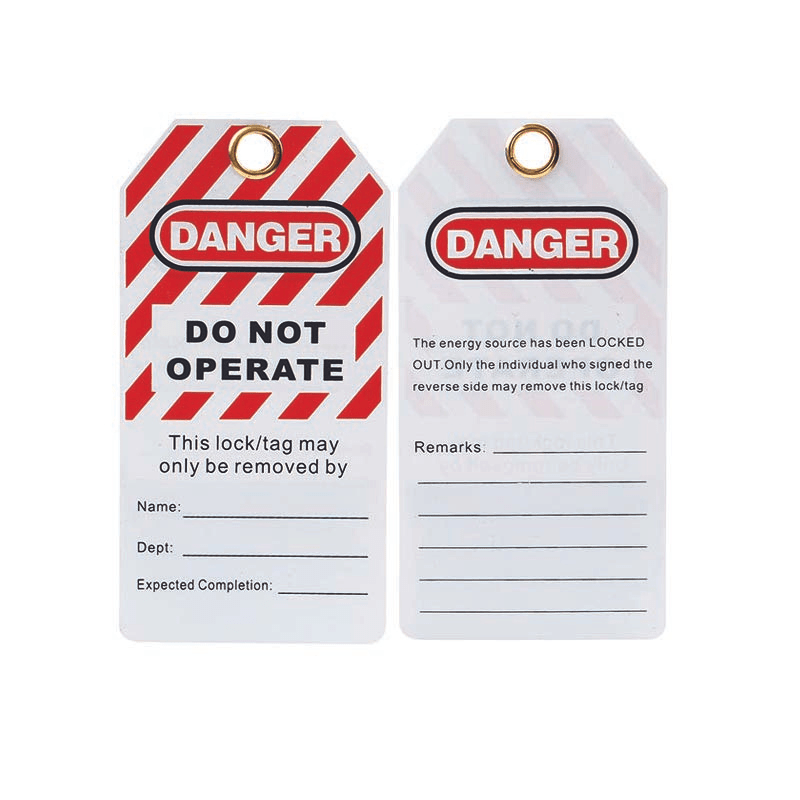

- Document: Sign and date the attached inspection tag. Keep a more detailed record in a central logbook. This documentation is critical during a safety audit.

The Annual Compliance Inspection

Once a year, a more thorough inspection must be performed by a qualified person. This includes:

- Verifying it still meets the 10-second rule from all hazards.

- Measuring the flow rate and spray pattern with proper testing equipment.

- Checking the water temperature.

- Ensuring all components are in good working order and signage is still visible.

Employee Training

The best equipment is useless if your team doesn't know how to use it. All lab personnel must be trained on the location and proper operation of their nearest safety stations. Conduct annual refresher training and drills.

Save time and ensure compliance. Download the HAWS PDF checklist for best practice inspections here!

Conclusion

Choosing, installing, and maintaining the right laboratory safety shower is a foundational pillar of your facility's safety culture. It is a tangible demonstration of your commitment to protecting your most valuable asset: your people. By moving beyond a simple "check-the-box" mentality and embracing a comprehensive approach—from a detailed risk assessment and correct product selection to strategic placement and diligent weekly maintenance—you can ensure your team has the protection it deserves. An investment in a high-quality, compliant system like a Haws Notduschen is not just an expense; it is a direct investment in a safer, more secure working environment.

Have questions or need a custom consultation for your lab? Contact our safety experts today for a no-obligation assessment.