EHS Insight is excellent software for managing incidents, audits, and training. But if you're searching for "EHS Insight lockout tagout" hoping to find a LOTO execution solution—you won't find one. Here's why that gap matters and what to do about it.

Let's address the elephant in the room: EHS Insight doesn't have a lockout tagout module.

Search their 32+ modules. You'll find Audit Management, Incident Management, Training Management, Compliance Tasks, Permitted Work, Job Safety Analysis, and dozens of other capabilities. What you won't find is a dedicated LOTO module for managing hazardous energy control procedures.

This isn't a criticism of EHS Insight—it's a recognition that comprehensive EHS platforms and specialised LOTO software solve different problems. EHS Insight has built a strong mid-market platform for safety management. But organisations with serious lockout tagout requirements need purpose-built tools for procedure execution, not just procedure documentation.

What EHS Insight Does Well

Before discussing the LOTO gap, credit where it's due. EHS Insight serves over 500,000 users with a well-designed platform that excels in several areas:

- Incident Management: Comprehensive tracking from report to resolution with root cause analysis

- Audit Management: Configurable checklists, scheduling, and corrective action workflows

- Training Management: Course delivery, completion tracking, and compliance reporting

- Compliance Tasks: Regulatory obligation tracking with automated reminders

- Mobile App: Offline-capable field access for audits and inspections

- Modular Pricing: À la carte structure starting at $4,600/year—pay for what you use

For mid-market organisations needing a unified EHS platform without enterprise complexity, EHS Insight delivers genuine value. Their AI Copilot for data analysis and SIF precursor identification shows continued innovation.

But none of this helps your maintenance technician execute a lockout procedure correctly at 2am.

The LOTO Gap: Documentation vs. Execution

EHS Insight offers LOTO-related resources—webinars on writing procedures, inspection form templates, energy control procedure templates. These are helpful for building your programme documentation.

What they don't offer is software that:

- Guides technicians through lockout execution step-by-step

- Verifies the correct equipment is being isolated

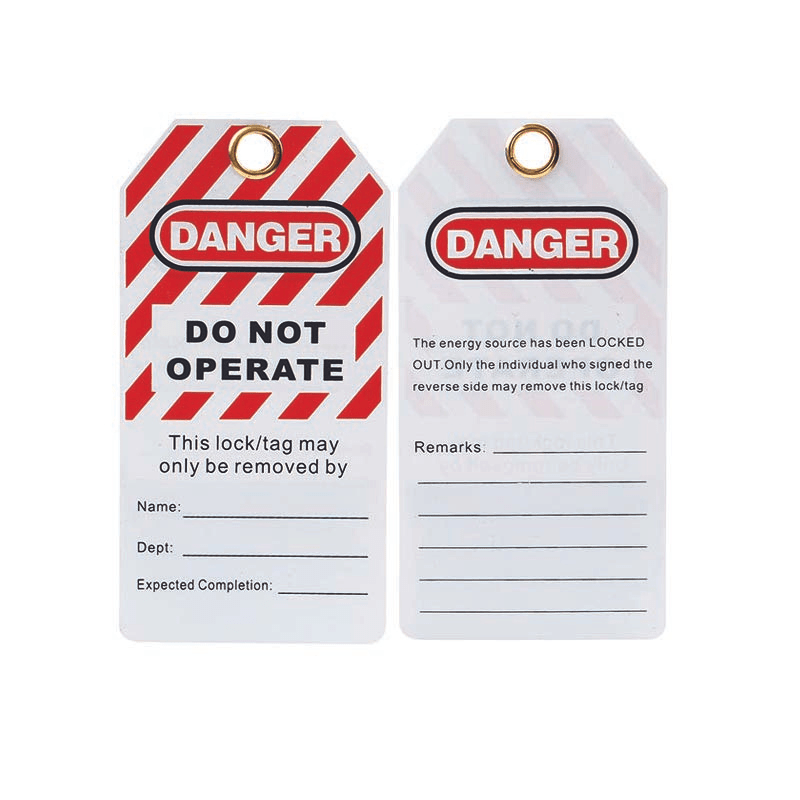

- Creates compliant tags linked to source procedures

- Captures digital audit trails of who locked out what, when, and why

- Ensures procedures are followed—not just written

This distinction matters because LOTO violations don't happen because procedures don't exist. They happen because procedures aren't followed.

OSHA's annual top 10 most cited violations list has included lockout tagout for over 15 years running. The problem isn't that companies lack written procedures filed in binders. The problem is that those procedures don't make it to the point of execution—and when they do, there's no verification that they're being followed correctly.

A technician needs to service a machine at 6:30am. The procedure is in a binder in the supervisor's office. The supervisor doesn't arrive until 7:00am. The technician has done this job dozens of times. They proceed from memory. They miss an energy source that was added during last month's modification.

This scenario plays out in facilities every day. Written procedures don't prevent it. Digital execution tools do.

Two Platforms, Two Problems

Understanding when to use EHS Insight versus when you need dedicated LOTO software comes down to the problem you're solving:

| EHS Insight Solves | Dedicated LOTO Software Solves |

|---|---|

| Tracking incidents after they happen | Preventing incidents during hazardous work |

| Managing training completion records | Guiding correct execution in the field |

| Scheduling and documenting audits | Verifying correct equipment isolation |

| Storing procedure documents | Delivering procedures at point of execution |

| Compliance obligation tracking | Creating audit trails of LOTO activities |

| Centralised EHS data management | Generating compliant tags from procedures |

These aren't competing capabilities—they're complementary. Many organisations need both: a platform for EHS programme management AND specialised tools for high-risk procedure execution.

Real Scenarios: Where Does Each Platform Fit?

OSHA requires annual inspection of each written LOTO procedure. You need to schedule inspections, assign inspectors, document findings, and track corrective actions.

Night shift maintenance needs to isolate a packaging line for bearing replacement. They need the procedure, must verify correct isolation points, and need to document the lockout.

A worker sustains a hand injury. You need to document the incident, conduct investigation, identify root causes, assign corrective actions, and track to completion.

You need professional tags for 200 pieces of equipment, each linked to the correct procedure, with QR codes for field access.

An auditor asks for evidence that LOTO procedures are being followed. They want to see records of actual lockout activities, not just written procedures.

The Complementary Approach

Rather than choosing one platform for everything, consider a complementary approach:

Use EHS Insight for:

- Incident management and investigation

- Safety training delivery and tracking

- Audit scheduling and management

- Compliance obligation tracking

- General EHS programme oversight

Use dedicated LOTO software for:

- Procedure creation and management

- Guided lockout execution in the field

- Equipment verification during lockout

- Tag creation linked to procedures

- LOTO-specific audit trails

This division of labour puts each tool where it's strongest. EHS Insight manages your broader safety programme; specialised LOTO software ensures your highest-risk procedures are executed correctly.

Zentri: Purpose-Built for the Execution Problem

Zentri exists specifically because general EHS platforms—however capable—don't solve the LOTO execution problem.

What makes Zentri different:

- QR Code Verification: Technicians scan equipment QR codes during lockout, confirming they're isolating the correct asset. This prevents wrong-equipment errors before they happen—something document storage can't do.

- Intelligent Tag Creation: Generate professional, regulation-compliant lockout tags directly from your procedures. Each tag includes a QR code linking to its source procedure. What takes hours manually takes minutes with Zentri.

- Procedure-Tag Integration: Tags and procedures live in a single connected system. Update a procedure, linked tags reflect the change. No version mismatches or outdated tags creating confusion.

- Built for Two Audiences: Frontline technicians get intuitive execution tools they'll actually use. EHS managers get complete programme oversight—analytics, compliance reporting, procedure usage tracking across all sites.

- Audit-Ready from Day One: Every action captured with timestamps and user identification. When auditors ask for LOTO execution evidence, you have it.

Quick Comparison

| Capability | EHS Insight | Zentri |

|---|---|---|

| Platform Type | General EHS management | Dedicated LOTO software |

| LOTO Module | Not available | Core platform focus |

| Procedure Execution | Not supported | Guided step-by-step with verification |

| Equipment Verification | Not available | QR code confirmation during lockout |

| Tag Creation | Not available | Integrated engine with procedure linking |

| LOTO Audit Trail | Training records only | Complete execution history |

| Incident Management | Comprehensive module | Not the focus |

| Training Delivery | Full LMS with content library | Not the focus |

| Audit Scheduling | Comprehensive module | LOTO inspections supported |

| Pricing | From $4,600/year + modules | Simple per-user (quotes on request) |

| Best For | General EHS programme management | LOTO execution excellence |

Frequently Asked Questions

Can EHS Insight and Zentri integrate?

Yes. Zentri's API enables data exchange with EHS platforms. LOTO completion records can flow to EHS Insight for unified safety reporting, while each platform handles what it does best.

We already paid for EHS Insight. Why add another tool?

Because EHS Insight doesn't solve the LOTO execution problem—and that's not a flaw, it's a scope decision. You likely use multiple tools for different functions (CMMS for maintenance, ERP for operations, EHS software for safety). Adding dedicated LOTO software addresses a gap rather than duplicating capability.

Can we use EHS Insight's Permitted Work module for LOTO?

Permitted Work manages work permits, not lockout tagout procedures. While permits and LOTO can be related (some permits require LOTO), they're distinct processes. Permit management doesn't provide QR equipment verification, tag creation, or guided lockout execution.

What about EHS Insight's Job Safety Analysis module?

JSA identifies hazards and controls for tasks. It's part of planning work safely, but it doesn't guide LOTO execution or verify that lockout procedures are followed correctly. A JSA might identify that LOTO is required; Zentri ensures LOTO is performed correctly.

How quickly can Zentri deploy alongside our existing EHS Insight setup?

Weeks, not months. Zentri's focused scope means faster implementation. Your EHS Insight environment stays unchanged while Zentri addresses the LOTO execution gap.

The Bottom Line

If you're searching for LOTO capabilities within EHS Insight, you're looking in the wrong place—not because EHS Insight is deficient, but because it's designed for different problems.

EHS Insight manages your safety programme. Zentri executes your lockout tagout procedures.

For organisations where LOTO compliance matters—where wrong-equipment errors, procedure non-compliance, and manual tag creation represent real operational and safety risks—the answer isn't choosing between platforms. It's using each where it excels.

Ready to close the LOTO gap?